Market Data

December 3, 2014

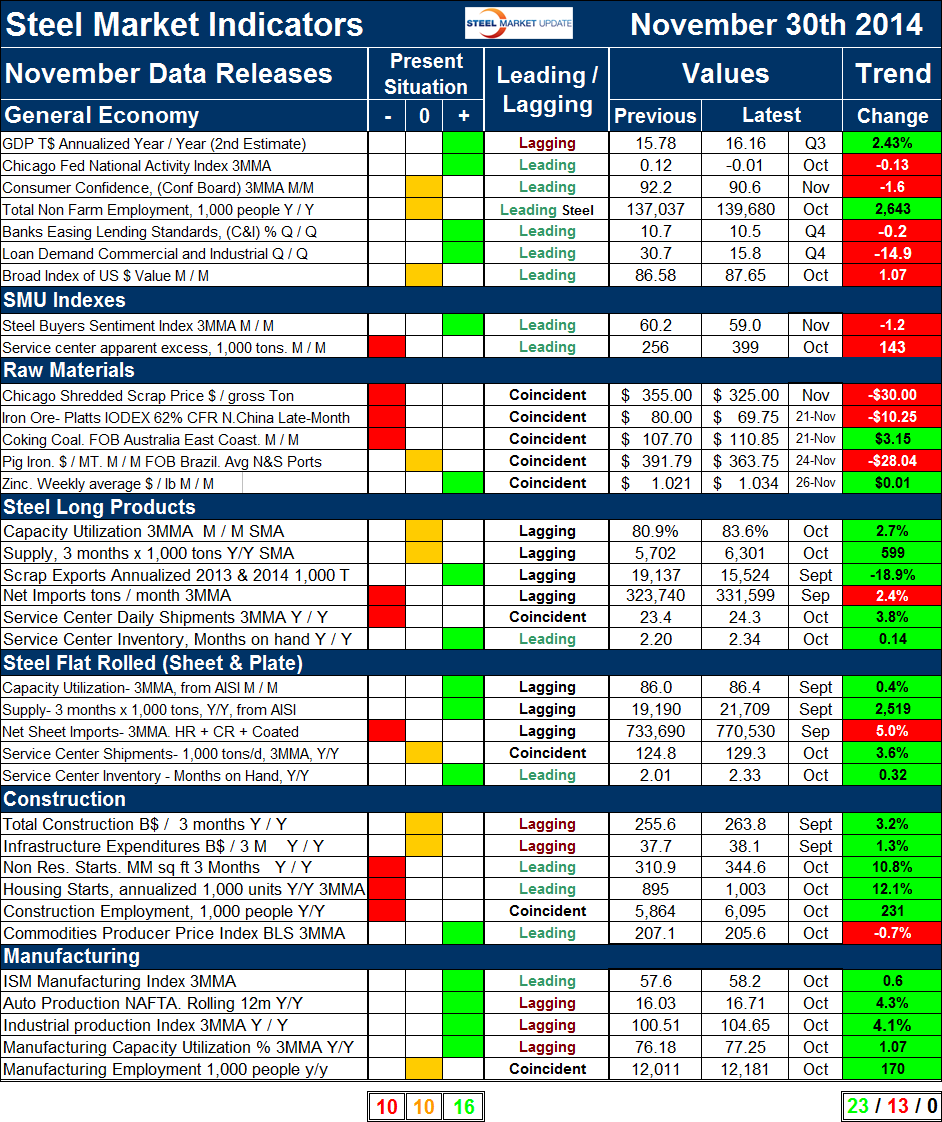

Key Market Indicators November 30th 2014

Written by Brett Linton

An explanation of the Key Indicators concept is given at the end of this piece for those readers who are unfamiliar with it.

The total number of indicators considered in this analysis is currently 36. The Chicago Fed Mid-West Manufacturing Index which was suspended earlier this year was expected to be re-instituted this month but has been postponed until spring 2015.

Please refer to Table 1 for the view of the present situation and the quantitative measure of trends. Readers should regard the color codes in the present situation column as a quick look at the current market condition. This is a subjective analysis based on our opinion of the level of each indicator. The “Trend” columns of Table 1, also by their color codes are designed to give a quick visual appreciation of the direction in which the market is headed. However the quantitative analysis of the value and direction of each indicator over time are the latest “facts” available. There is nothing subjective about this section which is designed for those readers who want to dig deeper. All data included in this table was released in November, the month or specific date to which the data refers is shown in the second column from the far right and all data is the latest available as of November 30th.

There has been small deterioration in the present situation and a substantial deterioration in trends since this analysis was last published a month ago.

Present Situation: Sixteen of the present situation indicators based on historical standards were positive on November 30th, ten were negative with ten considered to be close to the historical norm. This is a net increase of one negative and a decrease of one neutral.

The indicator changed this month was the price of Chicago shredded. We regard low raw materials prices as negative and in the case of Chicago shredded this boundary is at $350. In November the price declined by $30 to $325 per gross ton.

There were no other changes in the present situation.

The SMU buyer’s sentiment index which was at an all-time high in September continued to be very strong with a three month moving average of 59.0 in November. The buyer’s index is based on a survey of sheet producers and consumers and is not intended to be inclusive of long product market conditions. The service center excess continued to be a surplus which we regard as a negative for prices going forward as it suggests that service center inventories are on the high side.

In the raw materials section three out of five indicators, shredded scrap, iron ore and coking coal are now negative, the international price of pig iron is neutral and the price of zinc remains positive.

The present situation of the flat rolled steel sector continues to be better than for long products. Net imports continue to be high for both sectors. Capacity utilization and apparent supply continue to be neutral for long products and positive for flat rolled. One quick visual indicator in Table 1 is to compare the present situation of raw materials with that of the US flat rolled section lower in the table. Clearly the US market situation is stronger than the global market which promotes imports.

Construction continues to be weak to neutral and manufacturing continues to be neutral to strong. Both nonresidential and residential construction starts are rated historically negative as is the total number of people employed in construction. The only indicator rated positive in the construction category is the producer price index of commodities which we believe to be highly correlated with industrial construction activity, particularly in the energy sector. None of the manufacturing indicators on a present situation basis are currently negative. Four are positive and one, manufacturing employment is neutral.

Trends: Twenty three of thirty six indicators are still trending positive but this was a decrease of six from our October 31st report. October had been the best result since we began this analysis, November represents a return to the norm that has existed for the last 18 months.

Changes in the individual sectors are described below. (Please note in most cases this is not November data but data that was released in November for previous months.)

In the general economy, the second release of GDP for the 3rd quarter was revised up from 3.5 percent in the first estimate to 3.9 percent. In Table 1, GDP growth is reported as 2.43 percent which is the year / year rate and which we believe is more indicative of the real situation. The Chicago Fed National Activity Index which had declined in August reversed direction and expanded in September then declined very slightly in October. Consumer confidence as reported by the Conference Board declined in October for only the second time in seven months and gave back the September gain.

The trend of the SMU proprietary steel buyer’s index continued to be negative for the second straight month but is coming off the September value which was an all-time high. The service center excess rose from 256,000 tons to 399,000 tons. This is also a proprietary indicator developed by SMU for sheet products and which when in surplus indicates rising inventories and falling pricing power. SMU is forecasting an excess through March next year, this includes import material sitting on the docks.

Trends in raw materials changed significantly in the latest data. Chicago shredded fell as mentioned above. The price of scrap is responding to the price of iron ore and to the strengthening dollar. The price of iron ore declined in November after a brief respite in October and on the 21st of November the IODEX was <$70 per dmt. Coking coal entered this analysis for the first time last month with a declining trend but as of November 21st had reversed direction and picked up $3.5 per metric ton. The price of Brazilian pig iron (an average of Brazilian N and S port exports FOB) which had defied logic until November finally declined by $28 to $363.75 per metric ton. The price of zinc which had declined slightly in September picked up a cent in October and another in November to close at $1.034 per lb. on November 26th.

In the long products section, all indicators trended positive except for net imports which had declined in our October analysis so this was a reversal. Net imports of long products were zero in late 2011! Capacity utilization improved and demand (as measured by apparent supply) increased at a rate in excess of two million tons per year. Service center shipments increased for the seventh consecutive month but are still very depressed by historical standards.

In the flat rolled section there were no changes in the direction of trends. Capacity utilization increased by 0.4 percent to 86.4 percent in October and in three months through October supply increased at a rate <10 million tons per year compared to last year. This was the seventh straight month of increasing supply on a 3MMA basis. Net imports increased in September which is the latest month for which this data is available for the ninth straight month. Based on license data, imports of flat rolled continued to increase in October. Service center flat rolled shipments grew by 3.6 percent on a 3MMA basis year over year which was the fifteenth straight month of growth. Months on hand at the end of October were normal at 2.33

In the construction section there were no changes in the direction of trends, only one indicator, the price of commodities is trending negative. We regard this indicator as a driver of industrial construction which is still strong. Nonresidential and residential construction starts continue to improve but as we have reported elsewhere they both have a long way to go.

All trends in the manufacturing sector have been positive for seven straight months. The three month moving average of ISM manufacturing index rose to 58.2 in October, the highest level since May 2011. The industrial production index and auto production continue to expand at a 4.1 percent and 4.3 percent rate respectively. Manufacturing employment grew by 170,000 year over year, less than construction which added 231,000 positions.

The key indicators analysis is still looking good in spite of the declines this month. SMU has several benchmark analyses that show steel demand has recovered more slowly than the general economy and is still not where it should be at this stage of a recovery. This is because the recession in non residential and housing construction was so extreme. Steel supply is now beginning to close the gap as construction slowly picks up the pace.

We believe a continued examination of both the present situation and direction is a valuable tool for corporate business planning.

Explanation: The point of this analysis is to give both a quick visual appreciation of the market situation and a detailed description for those who want to dig deeper. It describes where we are now and the direction in which the market is headed and is designed to give a snapshot of the market on a specific date. The chart is stacked vertically to separate the primary indicators of the general economy, of proprietary Steel Market Update indices, of raw material prices, of both flat rolled and long product market indicators and finally of construction and manufacturing indicators. The indicators are classified as leading, coincident or lagging as shown in the third column.

Columns in the chart are designed to differentiate between where the market is today and the direction in which it is headed. It is quite possible for the present situation to be predominantly red and trends to be predominantly green and vice versa depending on the overall direction of the market. The present situation is sub-divided into, below the historical norm (-), (OK), and above the historical norm (+). The “Values” section of the chart is a quantitative definition of the market’s direction. In most cased values are three month moving averages to eliminate noise. In cases where seasonality is an issue, the evaluation of market direction is made on a year over year comparison to eliminate this effect. Where seasonality is not an issue concurrent periods are compared. The date of the latest data is identified in the third values column. Values will always be current as of the date of publication. Finally the far right column quantifies the trend as a percentage or numerical change with color code classification to indicate positive or negative direction.