Market Segment

April 24, 2020

CRU: How Blast Furnaces Can Be Idled

Written by CRU Americas

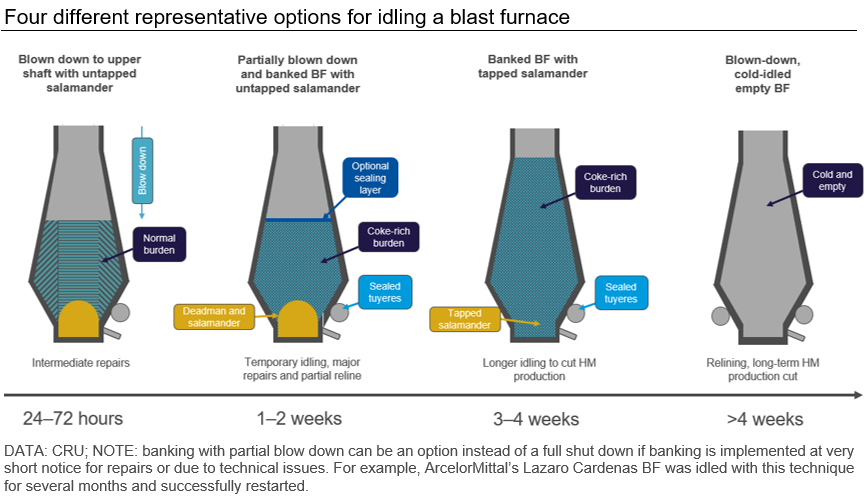

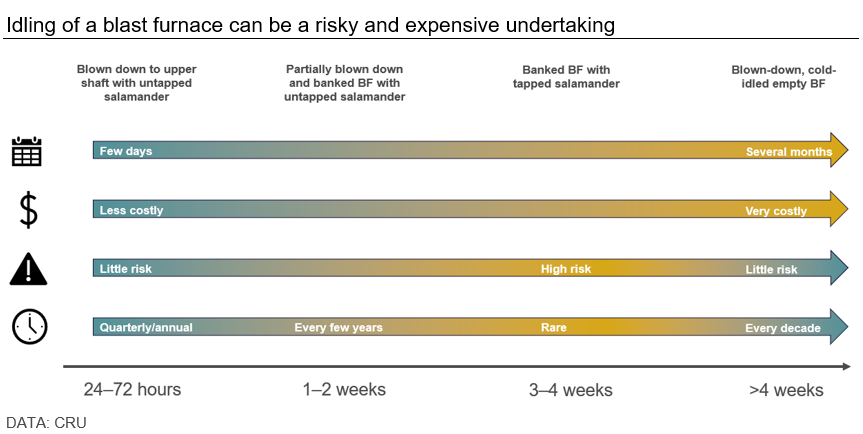

The global Covid-19 outbreak has resulted in sharply falling steel demand all over the world. For the steel industry, it is a challenging task to reduce production levels as ~70 percent of global output is produced through the BF/BOF, or integrated steelmaking, process route. Blast furnaces (BFs) suffer from low operational flexibility—they cannot typically be operated below ~75 percent of nominal capacity for operational and costs reasons—but switching off can be a difficult, risky and expensive process, which puts mills in a challenging position when markets contract significantly. So, what does it actually mean to idle a blast furnace?

BFs are, by nature, complicated and expensive to halt. In this insight, we aim to illustrate the techniques to idle a BF in the short term, meaning it is relatively easy to bring it back to production. There is also a longer-term option, for which a BF remains out of operation for longer time periods, but with high restart costs.

In the current Covid-19 situation, CRU has seen a difference in the options chosen to idle BFs in different parts of the world, suggesting different expectations for the length of demand loss in those regions. For example, steelmakers in Japan and India appear to have preferred the shorter-term “banking” option, whereas those in the USA and Europe have opted for the longer-term “blow down” or cold-idle option. Each of these options are explained below.

Banking’s the Preferred Option for Temporary Idling…

A BF can be banked (i.e. “hot idled”) to stop hot metal output temporarily. The most common duration for banking is 1-4 weeks, but it can be extended if necessary. The process of banking puts the BF into a mode of hibernation such that the hot blast, raw materials charging and hot metal production is stopped. BFs can be banked for up to several months, but the risk of an unsuccessful restart increases strongly with time making cold idling (n.b. see below) the preferred choice for most BF operators for stops longer than four weeks.

The main aim of banking is the preservation of heat in the furnace because it strongly simplifies the restarting procedure. Therefore, measures are taken to reduce heat loss, such as sealing the furnace, but slow heat loss cannot be prevented.

Shorter hot idlings last for 1–3 days and are typically carried out to do maintenance. This is a well-understood process that is regularly performed as BF repairs and minor maintenance are often carried out several times per year. When repairs are finished, operations can resume as normal after a brief ramp-up.

For longer idlings that last 1-4 weeks, the operators stop adding iron ore to the BF and instead add a coke blank with subsequent layers of lean, coke-rich burden. This prohibits the melting process inside the BF and is often done for extended maintenance, repairs or at times when hot metal is not needed, for example, at times of short-term steel demand weakness.

The longer the hot idle lasts, the lower the temperatures become in the BF, risking solidification of the salamander (i.e. a term for the hot heel in the lower hearth). Restarting a BF with a solid salamander increases the risk of damaging the hearth (i.e. requiring full shut down and costly lengthy repair) and an unsuccessful restart. Therefore, removing the salamander, which itself is a risky undertaking and success is not guaranteed, could become necessary for week-long banking.

Operators in Japan, India and the U.S. have chosen the banking method to idle their BFs in the recent downturn, which implies they are expecting a relatively quick resumption of steel end-use activity as economies recover from the Covid-19 outbreak, but this is not the case elsewhere (n.b. see below).

…But a Full Shutdown is Preferred for Longer Outages

A complete blow-down before cold-idling is necessary for stopping a BF for several months and occurs for two primary reasons. The first is to reline the BF, which means replacing the refractories on the inside of the furnace. This is typically done once every 10-25 years and takes 3-4 months. Another reason to “cold idle” a BF is to stop production for longer time periods. This type of outage also provides the opportunity to perform repairs of commonly inaccessible parts of the BF, which may be another reason why an operator chooses this option over banking.

Cold-idling of a BF starts with blow-down of the burden to the tuyere level, followed by quenching and emptying the remaining burden inside the cold-furnace. The process of “cold idling” a BF and restarting is costly and time-consuming, as extensive planning and expertise are required. However, the operational risks of restarting an empty and cold BF are low as it is frequently carried out due to the numerous relinings taking place in the steel industry each year. Many BF operators in Europe and some in the U.S. have chosen recently to cold-idle their BFs, indicating the expectation of a steel demand weakness extending over months.

To learn more about the process of idling BFs and various technical aspects that need to be considered, reach out the contact below:

Alexander Ordosch, Analyst, +44 20 7903 2215

Erik Hedborg, Senior Analyst, +44 20 7903 2186

Paul Butterworth, Research Manager, +65 6232 2482

James Campbell, Principal Analyst, +44 20 7903 2267

Supplement: Banking, Shut Down, Blow-in—Defining Some Jargon

Banking (temporarily idling a BF): The BF is partly filled with a high-coke burden (n.b. similar to a “blow-in” burden) prior to complete shutdown, allowing quick start-up. It is synonymous to “hot-idling” and “off-wind.”

Shut Down (stopping the BF): The first step in a BF shut down is to discontinue the charging of fresh burden. The hot blast and hot metal production are continued until the burden is blown down to a low level. A full shut down includes emptying the BF and letting it cool down.

Deadman: Area of hot coke, slag and hot metal that resides permanently in the lower part of a BF.

Salamander: Area of coke and hot metal in the hearth of the furnace that can only be (partially) tapped with a special technique (salamander tap).

Blow-in (restarting the BF): Restarting a banked BF includes bringing the hot blast back on in stages to bring the BF back up to temperature. A cold-idled BF needs to be freshly charged with an iron-bearing burden that is coke rich (i.e. a blow-in burden), the hot blast is brought back on in stages and the BF brought back up to temperature. Blow-in is complete when normal operating parameters of the BF are reached.

Request more information about this topic.

Learn more about CRU’s services at www.crugroup.com