Market Segment

August 17, 2019

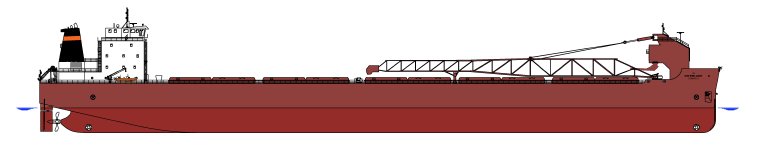

Lake Vessel to be Built with ArcelorMittal Steel

Written by Sandy Williams

ArcelorMittal Burns Harbor has the honor of providing the steel for the first U.S.-flagged Great Lakes bulk carrier to be built in more than 35 years.

“ArcelorMittal is privileged to serve as a steel supplier for the newest bulk carrier on the Great Lakes,” said Gary Mohr, VP of supply chain management at ArcelorMittal USA. “The expansion of Interlake’s fleet will further support water commerce and the movement of raw materials using the safest, most efficient and environmentally friendly method of transportation. The construction of a new bulk carrier is a great example of how the steelmaking process comes full circle.”

The new vessel will require 5,614 short tons of steel for the hull and superstructure. Most of the steel used will be sourced from Burns Harbor and the rest from a variety of foreign and domestic sources, said Interlake Steamship President Mark Barker.

“The first cut of steel is a major milestone that signifies we, along with Fincantieri Bay Shipbuilding, are ready to begin production on this historic project,” said Barker. “We are extremely proud to build our company’s first ship since 1981 on these freshwater shores with the hardworking women and men who help power our industry and with American-made steel from the iron ore we carry on our U.S. flag fleet vessels. It’s a true Great Lakes success story.”

Measuring 639 feet in length and 78 feet wide with a 28,000 gross ton capacity, the ship will transport raw materials to support manufacturing throughout the Great Lakes region. The ship was designed by Interlake, Fincantieri and Bay Engineering and includes advanced automated vessel and unloading systems.

The vessel is schedule for completion in mid-2022 and will be the tenth vessel in Interlake Steamship’s fleet.