Prices

August 28, 2018

Raw Material Prices: Iron Ore, Coking Coal, Pig Iron, Scrap and Zinc

Written by Peter Wright

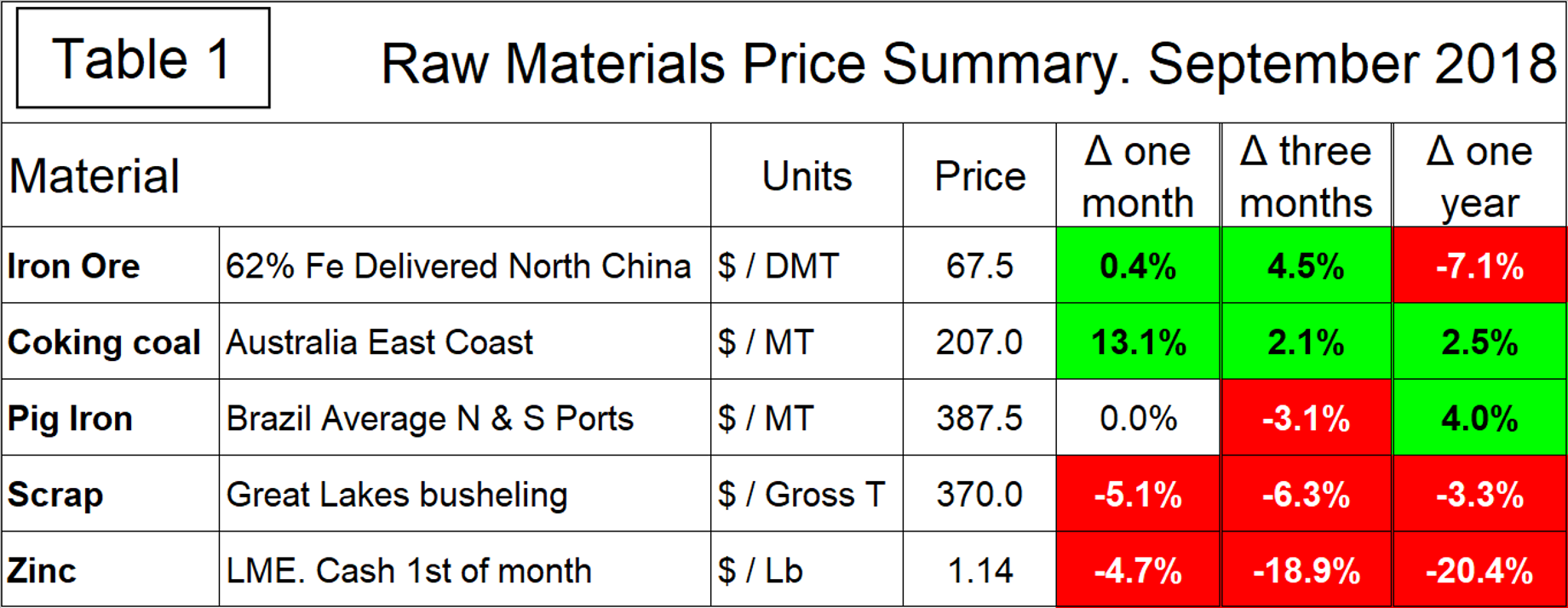

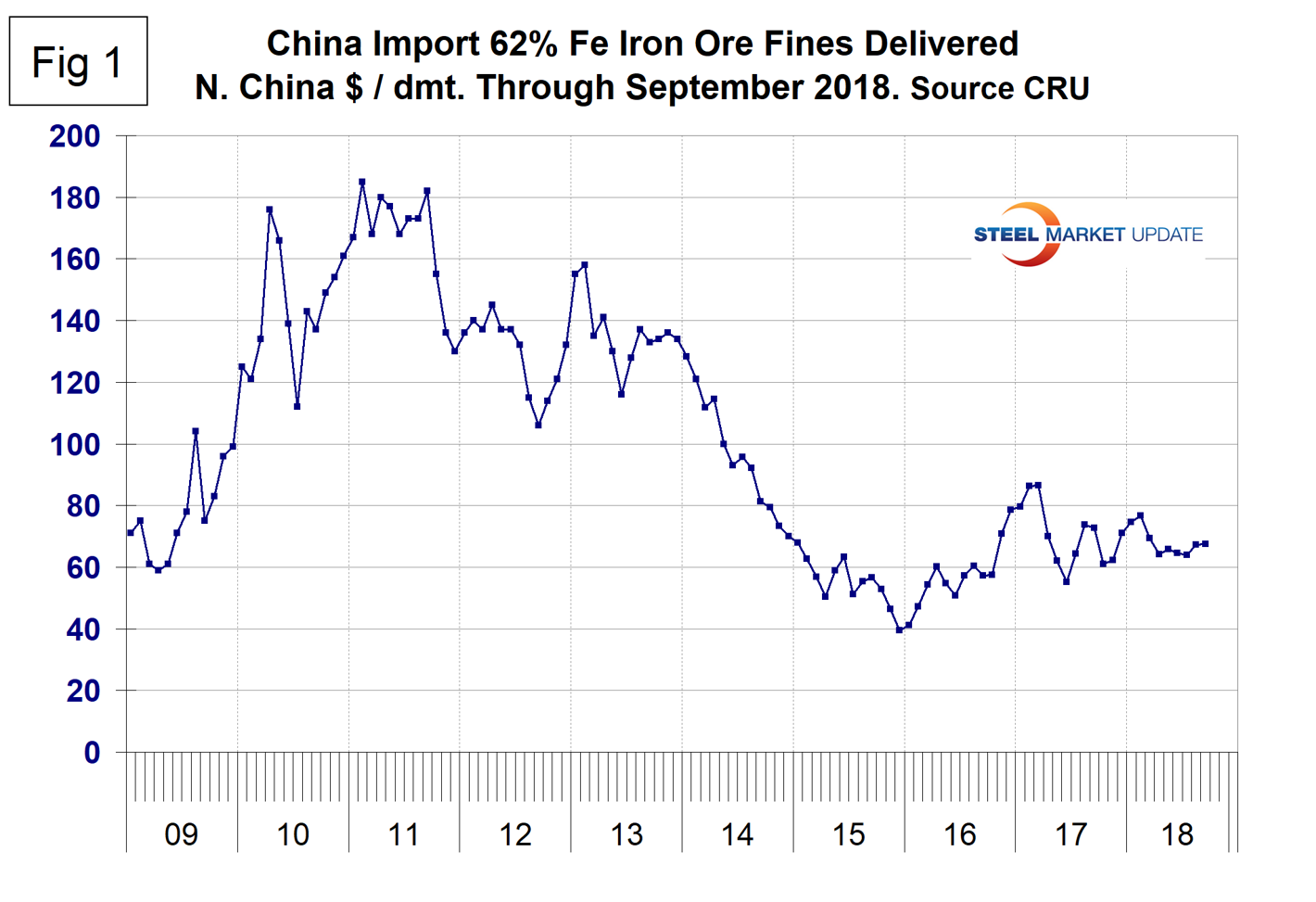

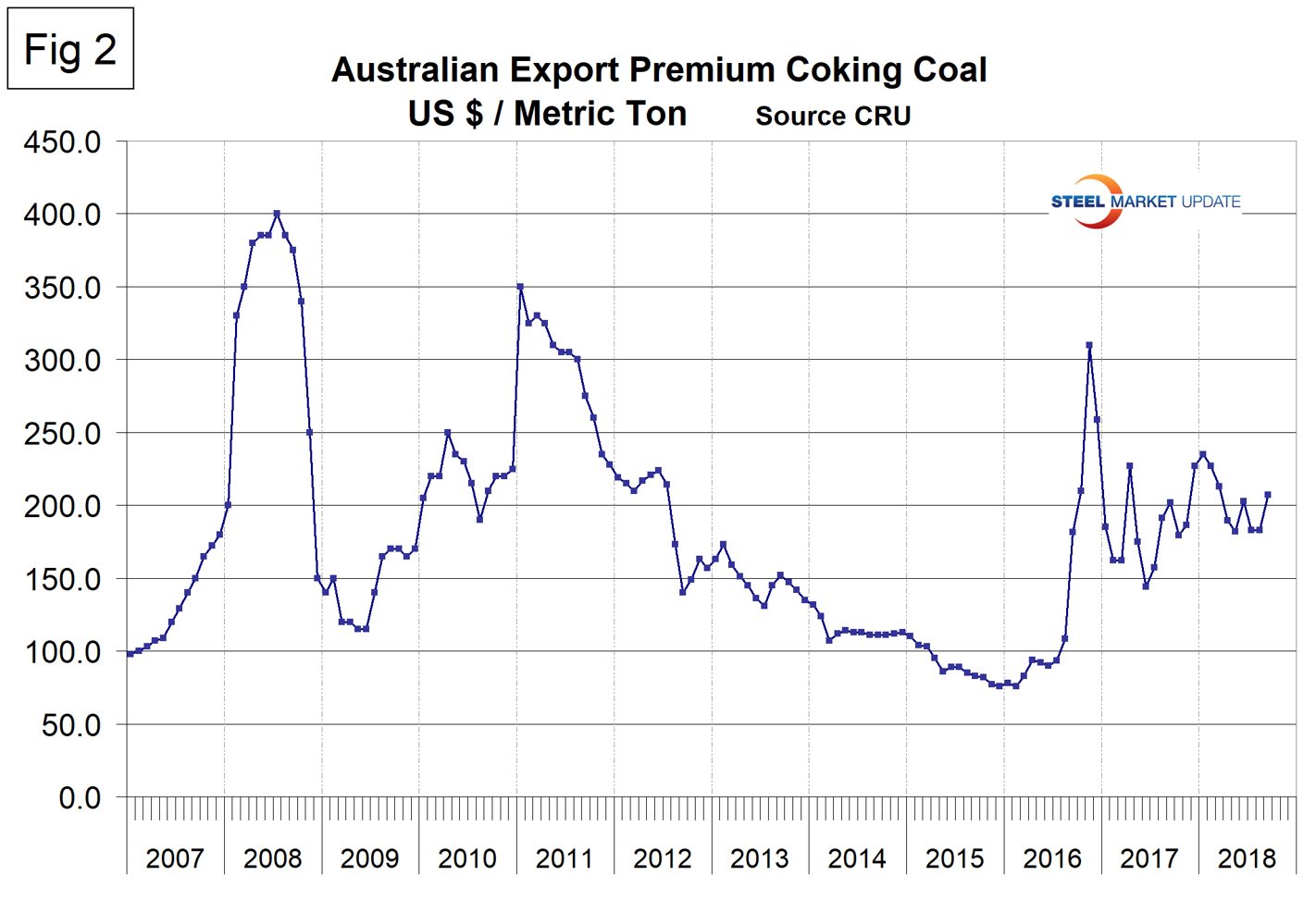

Recent price changes have been mixed for steelmaking commodities. In the last three months, coking coal and iron ore have trended up as pig iron, scrap and zinc have trended down. Table 1 summarizes the September prices of the five materials considered in this report and the month/month, three months/three months and year/year change.

Iron Ore

The weekly average spot price of 62% fines delivered North China was $67.50 per dry metric ton in mid-September. In one month, the price increased by 0.4 percent and in three months was up 4.5 percent. Year over year, the price in September was down by 7.1 percent. Figure 1 shows the price of 62% Fe delivered North China since January 2009.

Coking Coal

Coking coal prices have traded in a range in the last 18 months. From February 2016 to November 2016, the price of premium low volatile coking coal more than quadrupled from $76 to $310 per metric ton. Since then, the price has stabilized in the $200 range and in September stood at $207. (Figure 2).

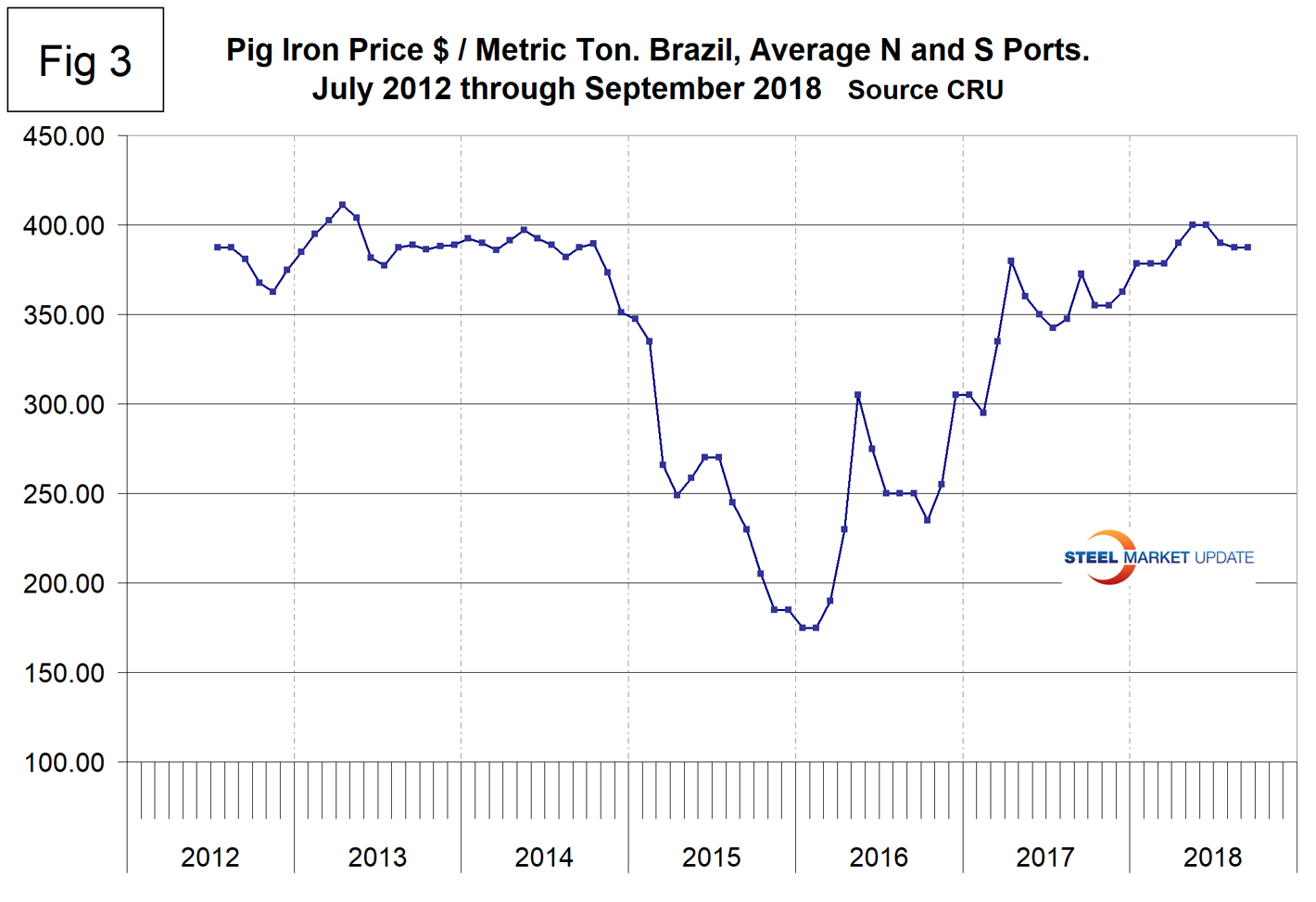

Pig Iron

Most of the pig iron imported to the U.S. currently comes from Russia, Ukraine and Brazil with additional material from South Africa and Latvia. In this report, we summarize prices out of Brazil and average the FOB value from the north and south ports. The price steadily increased from the $175 low point in January and February 2016 to $400 in May and June 2018 before declining to $387.50 in both August and September. In the last three months, the price of pig iron has declined by 3.1 percent (Figure 3).

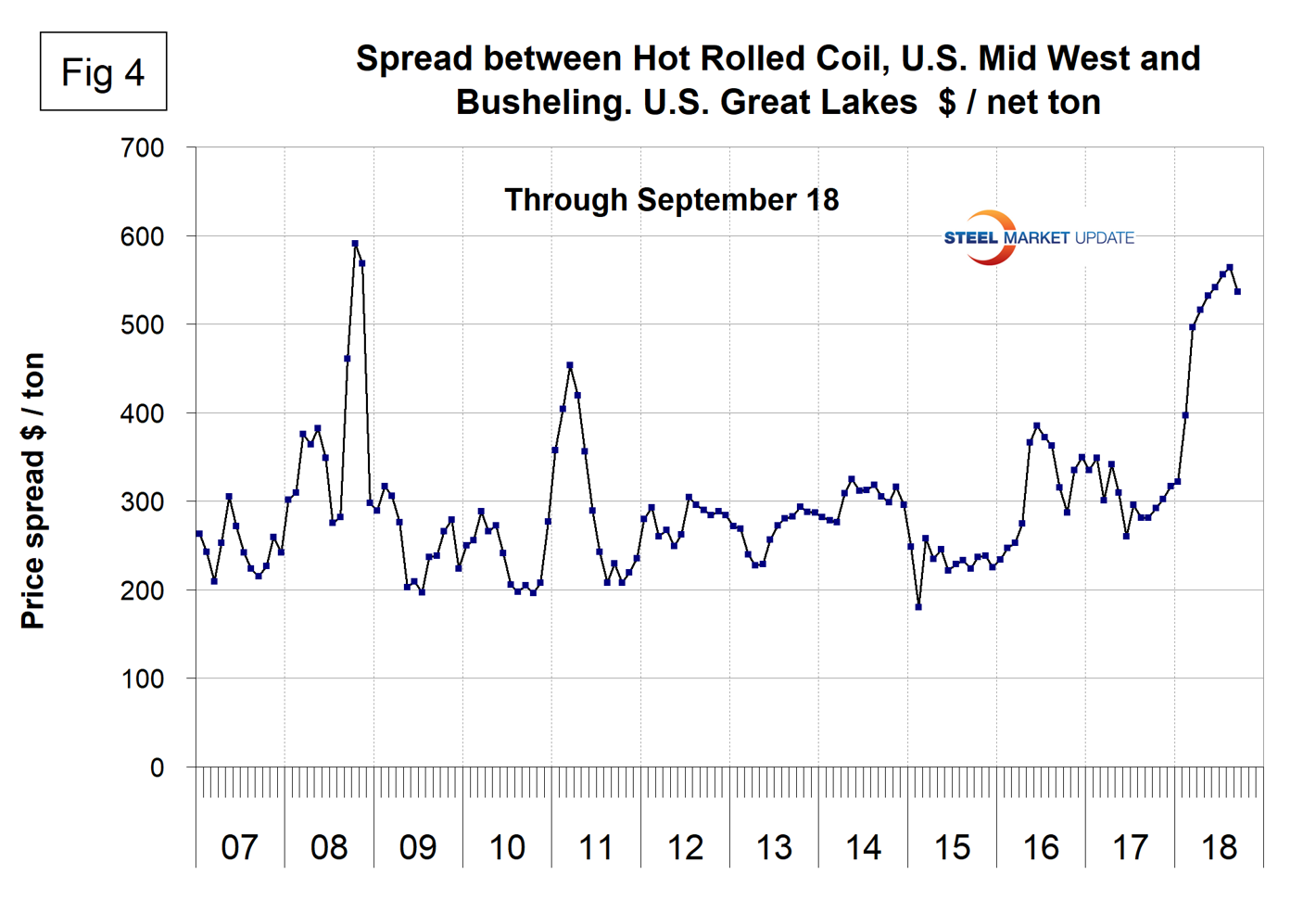

Scrap

To put this raw materials commentary into perspective, we include here Figure 4, which shows the spread between busheling in the Great Lakes region and hot rolled coil Midwest U.S. through early September 2018, both in dollars per net ton. The spread at $536.64 has declined by $27 from August, but is still historically very high. The spread has increased from $278.47 in September 2017.

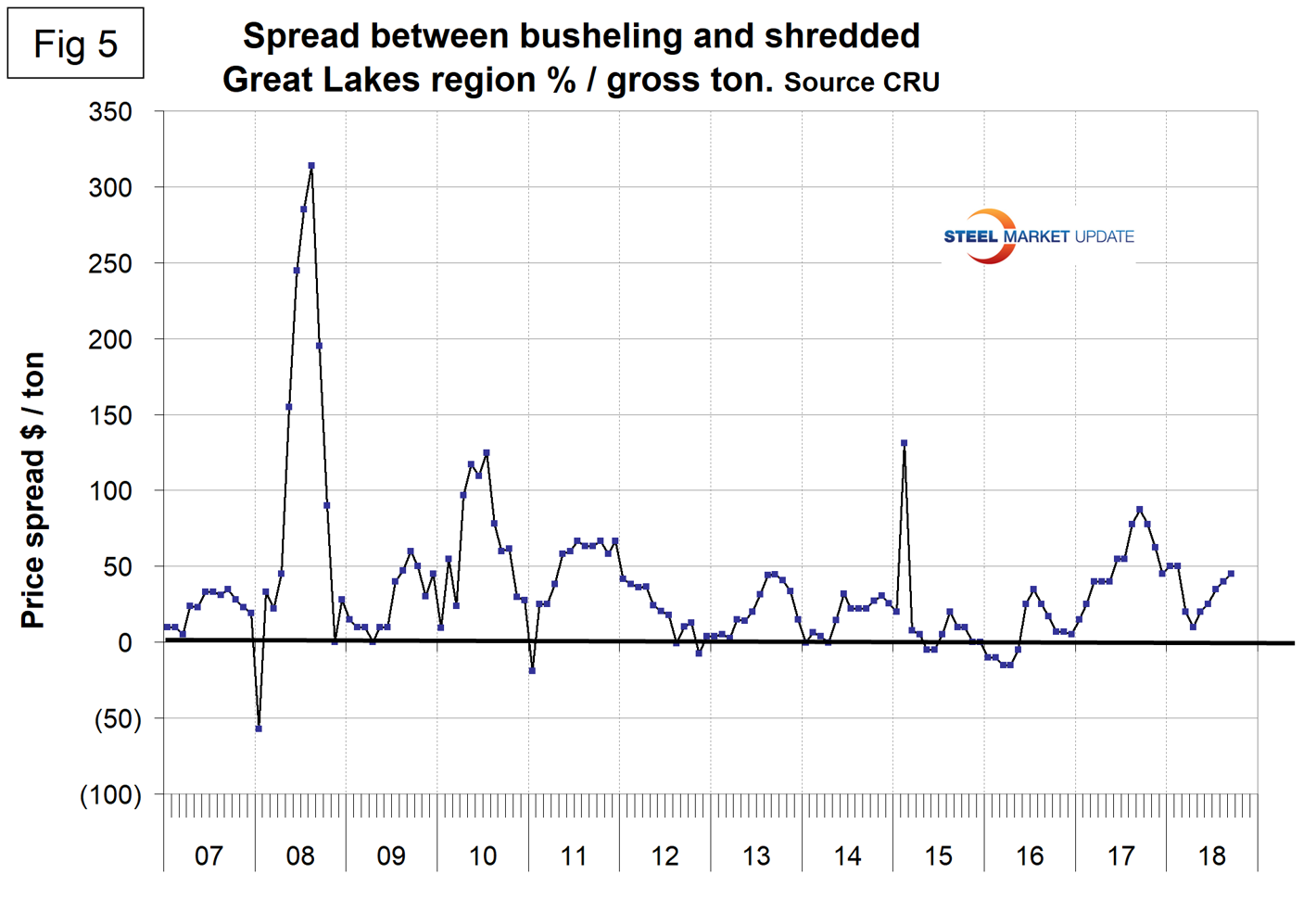

Figure 5 shows the relationship between shredded and busheling, both priced in dollars per gross ton in the Great Lakes region. This spread has been increasing for five months. The busheling premium over shredded rose from $10 in April to $45 in September.

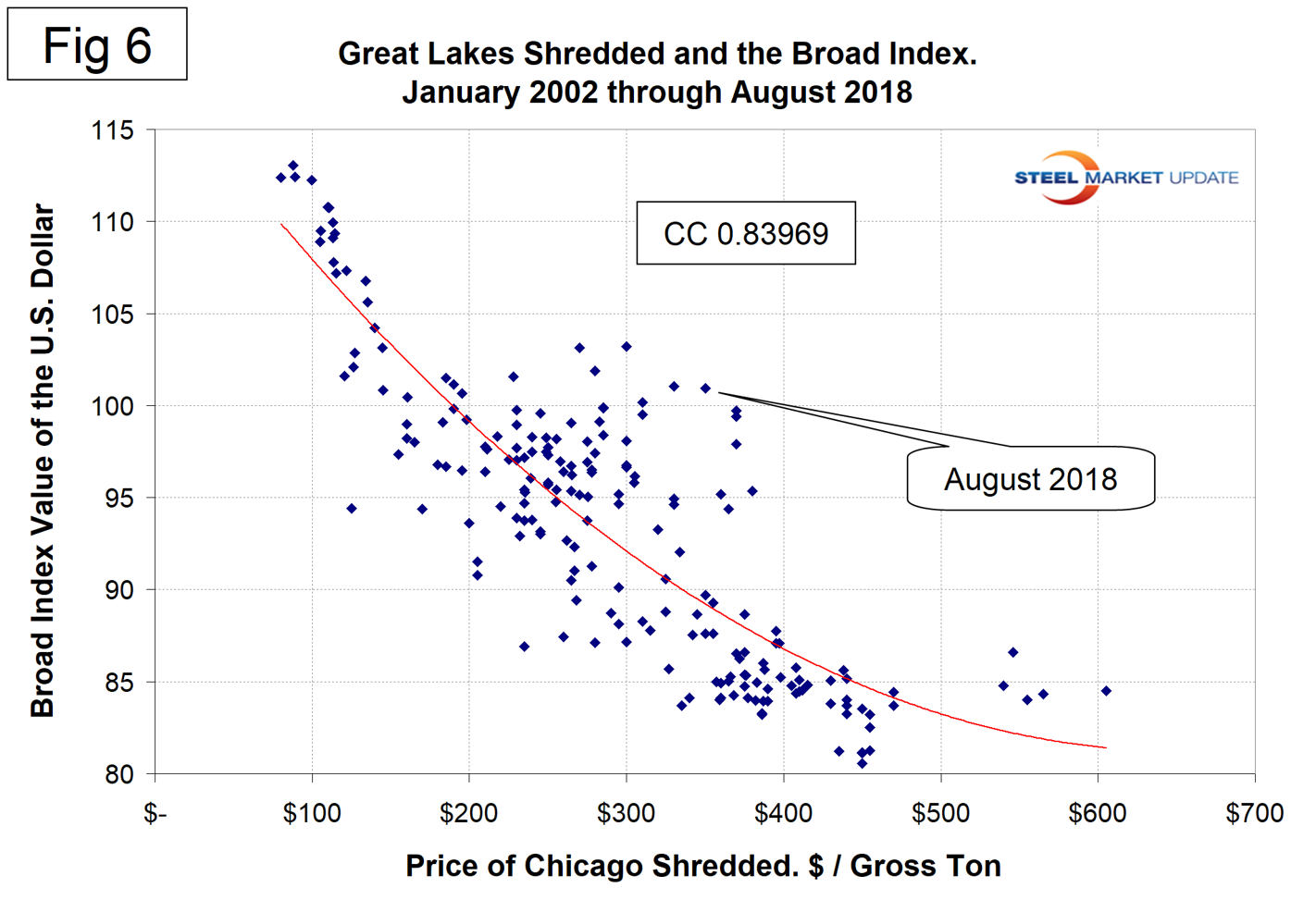

Figure 6 is a scatter gram of the price of Chicago shredded and the Broad Index value of the U.S. dollar as reported by the Federal Reserve. The latest data for the Broad Index was August. This is a causal relationship with a correlation of just less than 84 percent.

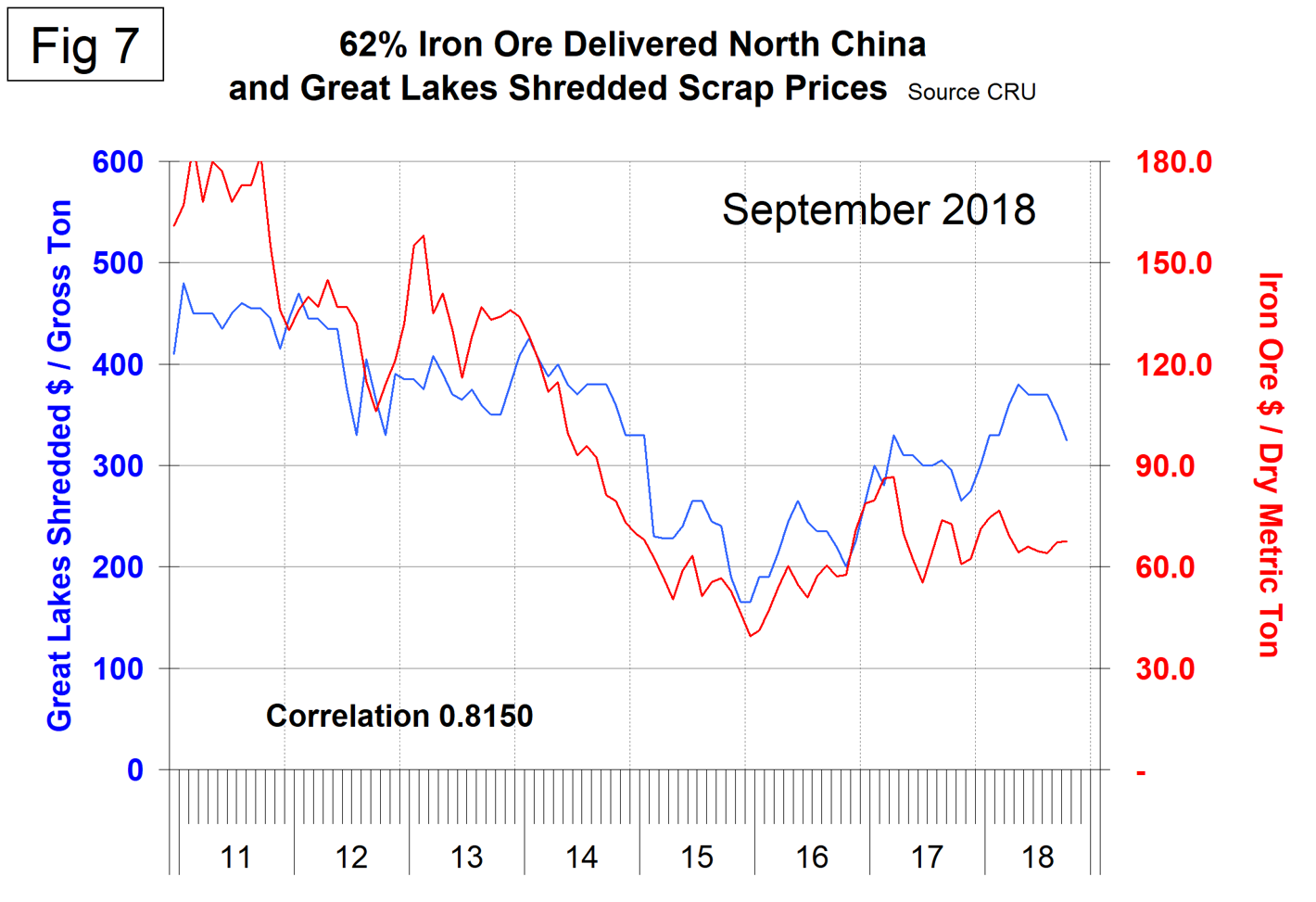

There is a long-term relationship between the prices of iron ore and scrap. Figure 7 shows the prices of 62% iron ore fines delivered North China and the price of shredded scrap in the Great Lakes region through early September 2018. The correlation since January 2006 has been 81.5 percent. There has been a very unusual divergence in these prices since Q2 2017.

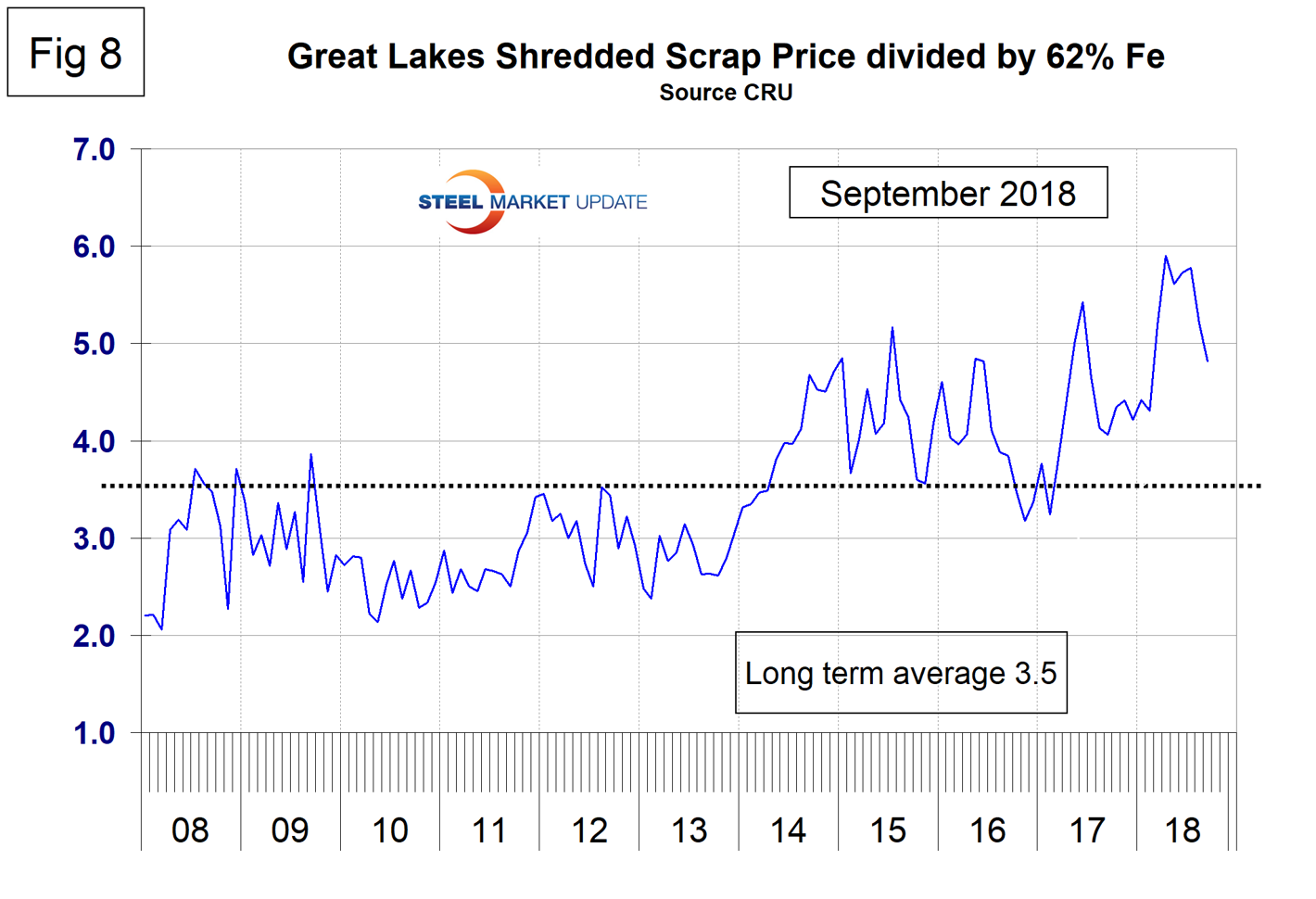

In the last 10 years, scrap in dollars per gross ton has been on average 3.4 times as expensive as ore in dollars per dry metric ton (dmt). The ratio has been erratic since mid-2014, but at 4.8 is highly beneficial to integrated producers (Figure 8). Since Chinese steel manufacture is 95 percent BOF, this ratio has allowed them to be more competitive on the global steel market. In the last four years, there have been times when China could supply semi-finished to the global market at prices competitive with scrap.

Zinc

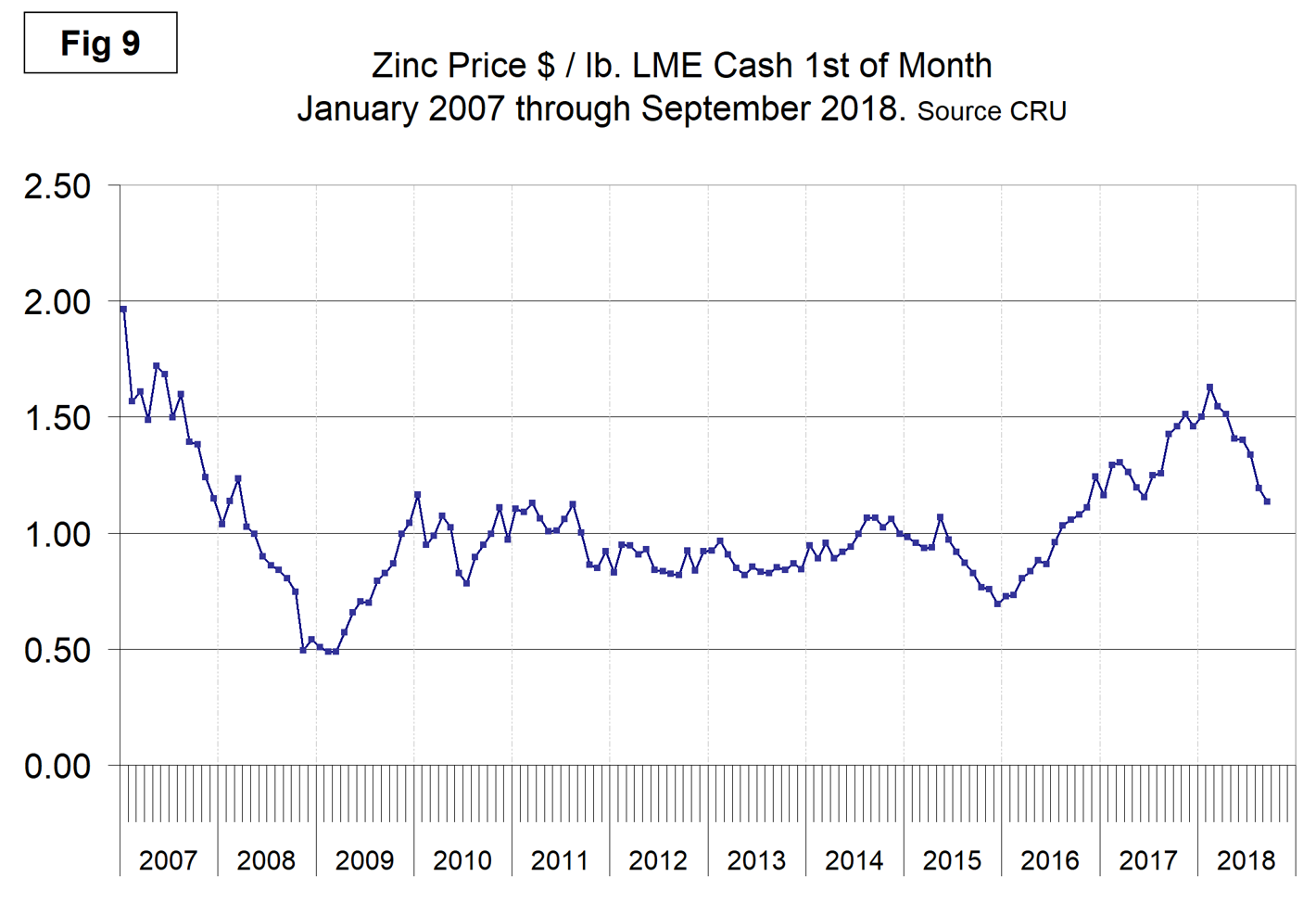

The LME cash price for zinc on the first of each month is shown in Figure 9. The price of zinc on Sept. 1 was $1.14 per pound, down from a high of $1.63 on Feb. 1. According to Bloomberg, zinc is the worst-performing base metal this year on the London Metal Exchange. “Continuously increasing LME inventories and weak Chinese demand added to worsening zinc fundamentals,” said Casper Burgering, an economist at ABN Amro Bank NV. “Supplies of zinc concentrates will continue rising. As a result, zinc prices will weaken further.”

Zinc is the fourth most widely used metal in the world after iron, aluminum and copper. Its primary uses are 60 percent for galvanizing steel, 15 percent for zinc-based die castings and about 14 percent in the production of brass and bronze alloys.

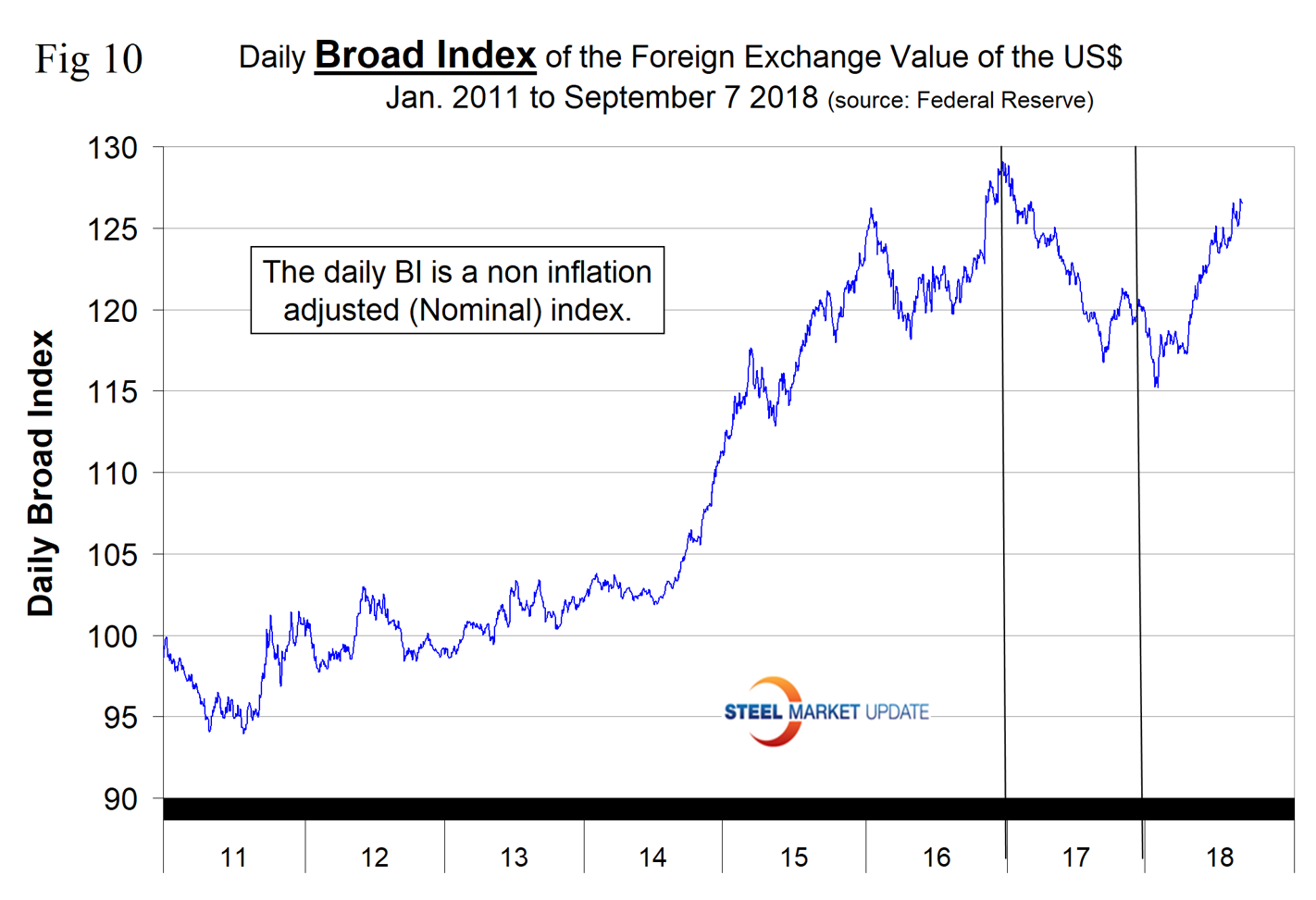

SMU Comment: There is an inverse relationship between commodity prices and the value of the U.S. dollar on the global currency markets. After falling for most of 2017 and through Feb. 1, 2018, the dollar has experienced a sharp upward revival and through Sept. 7 was up by 9.8 percent (Figure 10). Supply and demand fundamentals are the primary drivers of raw materials prices, but a rising dollar puts downward pressure on the price of those global commodities that are priced in dollars, as is clearly shown by the relationship between scrap and the dollar index described above in Figure 6.