Market Data

April 11, 2016

Shipments and Supply of Sheet Products through February 2016

Written by Peter Wright

This report summarizes total steel supply from 2003 through February 2016 and year on year changes. It then compares domestic mill shipments and total supply to the market. It quantifies market direction by product and enables a side by side comparison of the degree to which imports have absorbed demand. Sources are the American Iron and Steel Institute and the Department of Commerce with analysis by Steel Market Update.

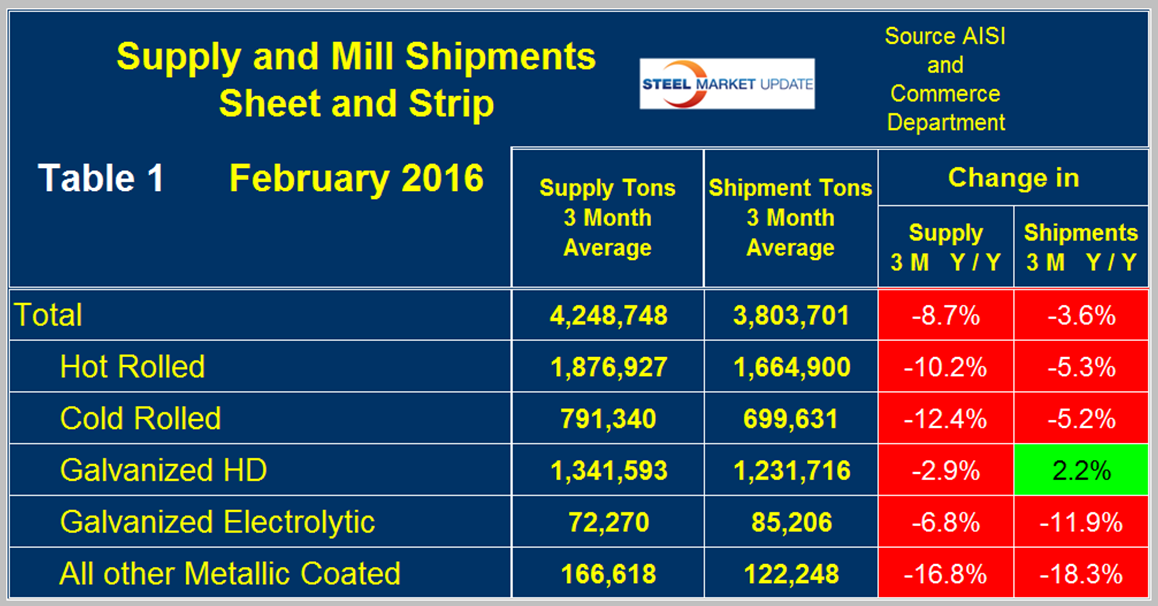

Table 1 shows both supply and mill shipments of sheet products (shipments includes exports) side by side as a three month average through February, for both 2015 and 2016.

Comparing these two time periods total supply to the market was down by 8.7 percent and shipments were down by 3.6 percent. The fact that supply was down by more than shipments means that imports put less pressure on the market than they did in most of 2015. Table 1 breaks down the total into the individual sheet products and it can be seen that for the big three items, HR and CR shipments declined by less than supply and HDG shipments increased. Supply of hot rolled was down by 10.2 percent and shipments were down by 5.3 percent, cold rolled supply was down by 12.4 percent as shipments were down by 5.2 percent. HDG supply was down by 2.9 percent as shipments were up by 2.2 percent. This means that in all three cases imports gave up some ground. Electro-galvanized lost ground to imports as supply was up by 2.6 percent and shipments were down by 6.1 percent. Electro galvanized enjoys a trade surplus which weakened in February. Other metallic coated products (OMC, mainly galvalume) also lost ground to imports as supply was down by 16.8 percent and shipments down by 18.3 percent. A review of supply and shipments separately for individual sheet products is given below.

Apparent Supply

Apparent Supply is a proxy for market demand and is defined as domestic mill shipments to domestic locations plus imports. In three months through February 2016 the average monthly supply of sheet and strip was 4.2 million tons, down by 8.7 percent year over year as mentioned above. In the three months through February supply was down by 0.9 percent compared to the period September through November. The short term decline (3 months) is less than the long term (12 months) which means that the decline is slowing. Table 2 shows the change in supply by product on this basis through February.

Momentum was positive for HR, CR and HDG products. Electro-galvanized and Galvalume both had negative momentum.

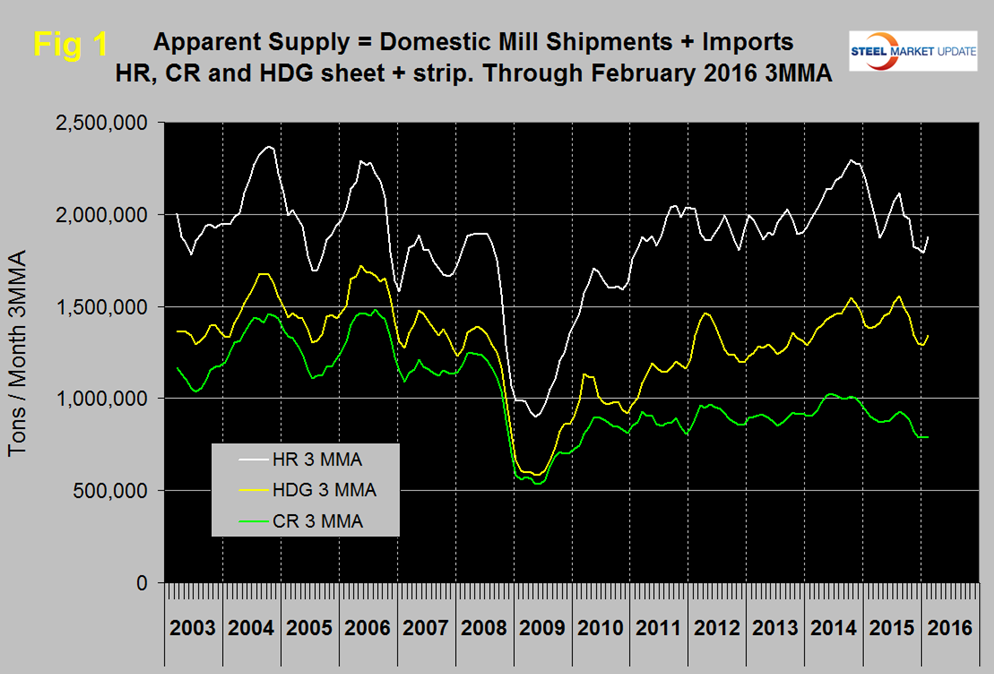

Figure 1 shows the long term supply picture for the three major sheet and strip products, HR, CR and HDG since January 2003 as three month moving averages.

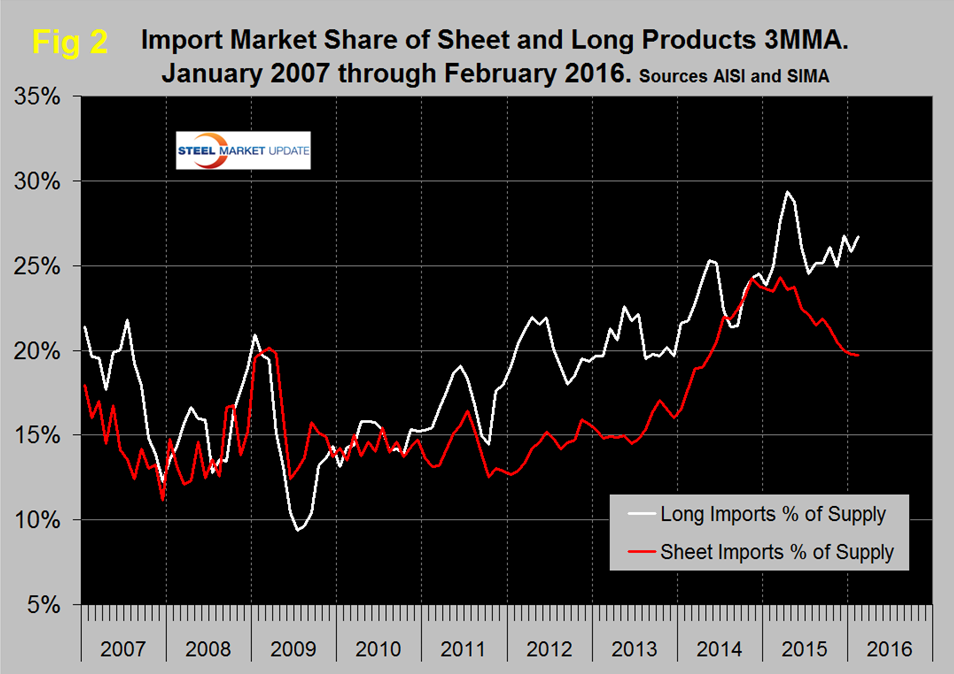

Figure 2 shows import market share of sheet products and includes long products for comparison.

Based on a 3MMA the import market share of sheet products has declined more or less continuously since March 2015 when it was 24.3 percent to 19.7 percent in February 2016. Long product import market share peaked at 29.4 in April last year, declined to 24.5 percent in July then increased erratically to 26.7 percent in this latest data.

Mill Shipments

Table 3 shows that total shipments of sheet and strip products including hot rolled, cold rolled and all coated products were down by 3.6 percent in 3 months through February year over year and up by 0.1 percent comparing three months through February with three months through November.

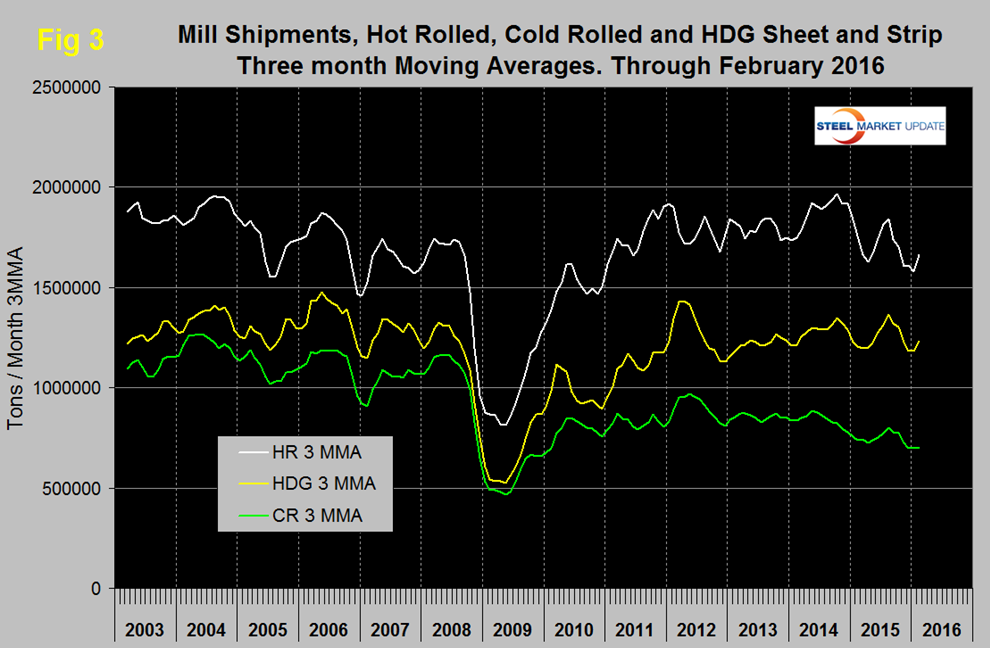

Year to date tonnage in the two months through February was up by 1.8 percent. Individual products performed quite differently, HR, CR and OMC had positive momentum meaning that the decline is slowing but for both galvanized products momentum was negative. Figure 3 puts the results for the three main products into the long term context since January 2003.

SMU Comment: The numbers in this report illustrate why it’s necessary to look at different time periods to try to understand the whole picture. We could draw opposite conclusions based on which time period we chose to describe. Our conclusion based on the results of our key market indicators analysis, buyer sentiment and the decline in service center excess is that February was an inflexion point and that for at least the next few months we will see a lot more green in the three tables included in this report.