Prices

May 31, 2022

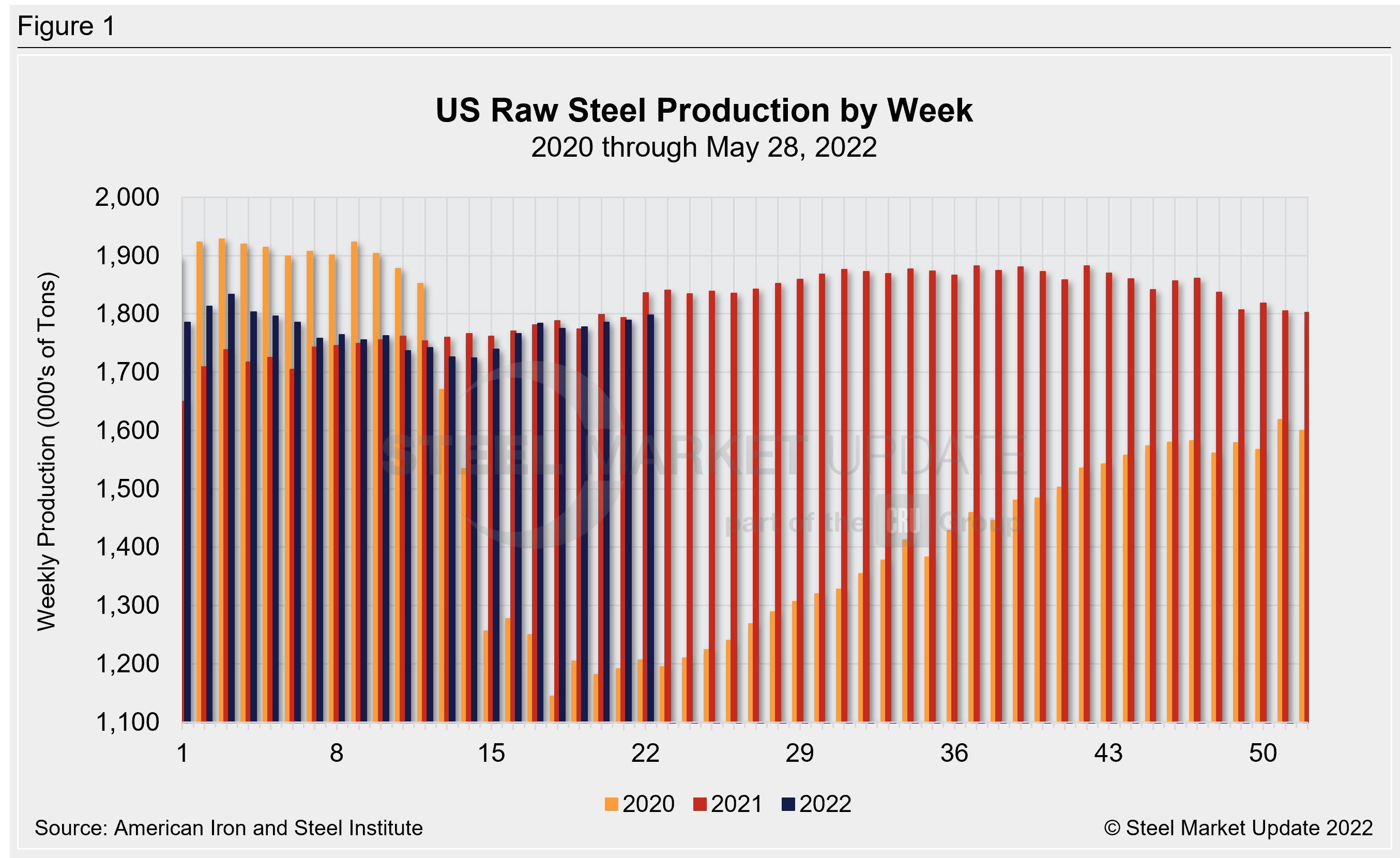

Raw Steel Production Gains Ground

Written by David Schollaert

Test Module 1 for both exec and Premium

Raw steel production by US mills grew last week, expanding for the fourth straight week, and reaching the second-highest utilization mark year-to-date. Domestic output totaled 1,798,000 net tons in the week ending May 28, while mill capacity utilization was 82.4%, reported the American Iron and Steel Institute.

US output was up 0.5% versus the week prior but 2.0% below the same year-ago period when production was 1,834,000 net tons. Mill capacity utilization last week was 0.3 percentage points above the prior week and 1.4 percentage points above the same period one year ago when utilization was 81%.

Based on this latest data, AISI’s weekly estimated domestic steelmaking capacity has decreased by 2.8% or 71,000 net tons over the past 12 months – from 2,252,000 net tons to 2,182,000 net tons. The downgrade would suggest the removal of 3.7 million net tons per annum of US steelmaking capability – a knockdown from 117.1 million net tons to 113.5 million net tons.

Adjusted year-to-date production through May 28 totaled 37,093,000 net tons, at an average utilization rate of 80.6%. That’s down 1.5% from the same period last year when production was 37,677,000 net tons, though the utilization rate was lower at 78.7%, AISI said.

Production slipped in three of five regions last week (Northeast, Midwest, and South). The declines were offset by a 3.5% increase (+20,000 tons) week-on-week in the Great Lakes district, while the West was unchanged over the same period.

Below is the production by region for the week ending May 28: Northeast, 168,000 tons; Great Lakes, 587,000 tons; Midwest, 205,000 tons; South, 767,000 tons; and West, 71,000 tons – for a total of 1,798,000 net tons, up 9,000 net tons from the prior week.

Note: The raw steel production tonnage provided in this report is estimated. The figures are compiled from weekly production tonnage provided by approximately 50% of the domestic production capacity combined with the most recent monthly production data for the remainder. Therefore, this report should be used primarily to assess production trends. The AISI production report “AIS 7”, published monthly and available by subscription, provides a more detailed summary of steel production based on data supplied by companies representing 75% of U.S. production capacity.

Given the large number of changes to steelmaking capability in the current rapidly evolving market environment, AISI is undertaking a comprehensive review of its raw steel production and capability utilization statistics to ensure that they accurately reflect market conditions. Any updates to capability will be phased in over several weeks.

By David Schollaert, David@SteelMarketUpdate.com