Market Data

August 14, 2021

Producer Prices Charge Forward in July

Written by David Schollaert

Steel Market Update is pleased to share this Premium content with our Executive members. For information on how to upgrade to a Premium-level subscription, email Info@SteelMarketUpdate.com.

Producer prices accelerated into midsummer, showing no signs of slowing down. The index and subcategories for final demand have fully recovered from the COVID-driven collapse and have overtaken pre-pandemic levels.

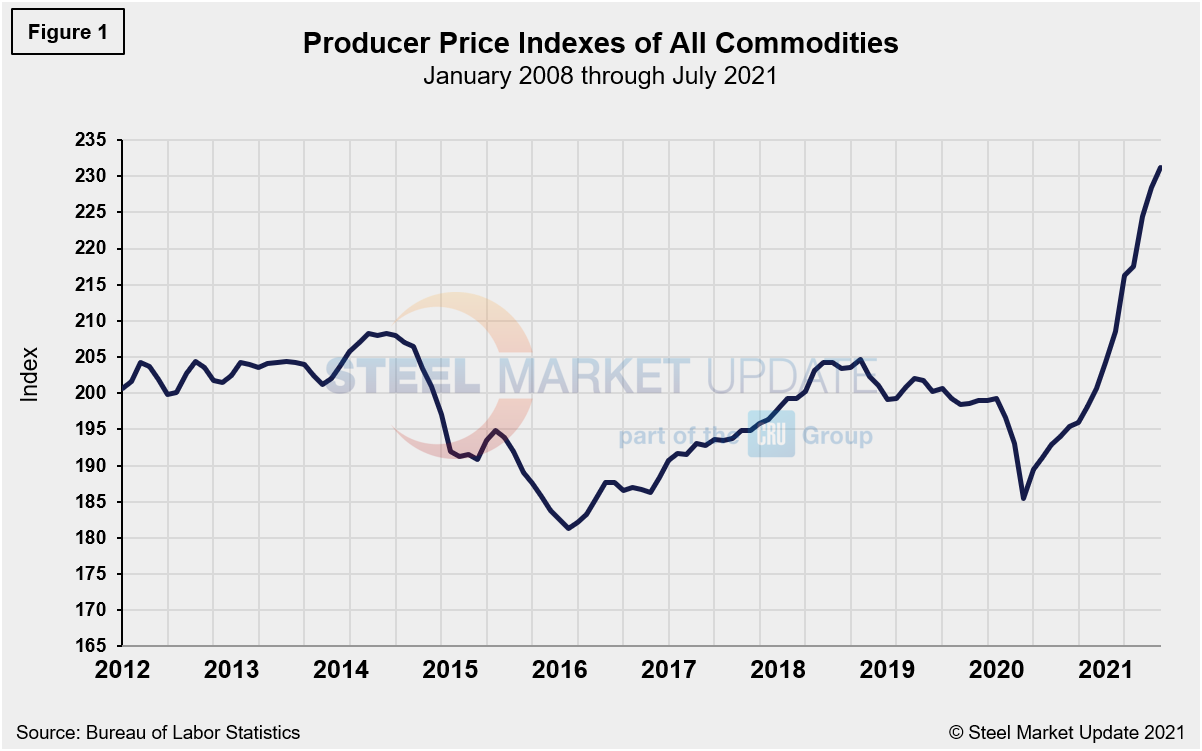

Since the collapse in early 2020, the composite Producer Price Index (PPI) of all commodities from the Bureau of Labor Statistics (BLS) has gained ground month-on-month for 14 consecutive months. July’s index registered a 1.2% increase versus the prior month, and a 19.9% increase year on year, seasonally adjusted. Additionally, the index is up 13.2% year-to-date, and is 11.0% higher than the previous high set in June 2014.

The PPI data, which covers more than 10,000 goods and services, is helpful in comparing the direction of price changes in the short and medium term. In specific, this analysis is intended to provide subscribers with a view of the relative competitive positions of sheet steel, aluminum, plastic and wood. It also includes some downstream products and a comparison of truck and rail transportation.

The composite PPI for all commodities (Figure 1) tumbled by more than 4.0% at the onset of the pandemic last spring. The recovery has been exceptional for the U.S. economy and historic for the steel industry. On an unadjusted basis, the final demand index moved up 19.9% for the 12 months ended in July, exceeding the prior month’s record advance of 19.6%, according to the BLS. The PPI is presently at 231.2 in July, up from 228.5 in June, and from 192.9 one year ago.

SMU’s benchmark hot-rolled coil price range stood at a record $1,880-$1,920 per net with an average of $1,900 per ton FOB mill, east of the Rockies as of Aug. 10, keeping its historic runup as evidence of rising producer prices. The latest increase is an astounding 78% higher than the previous record of $1,070 per ton seen in the summer of 2008.

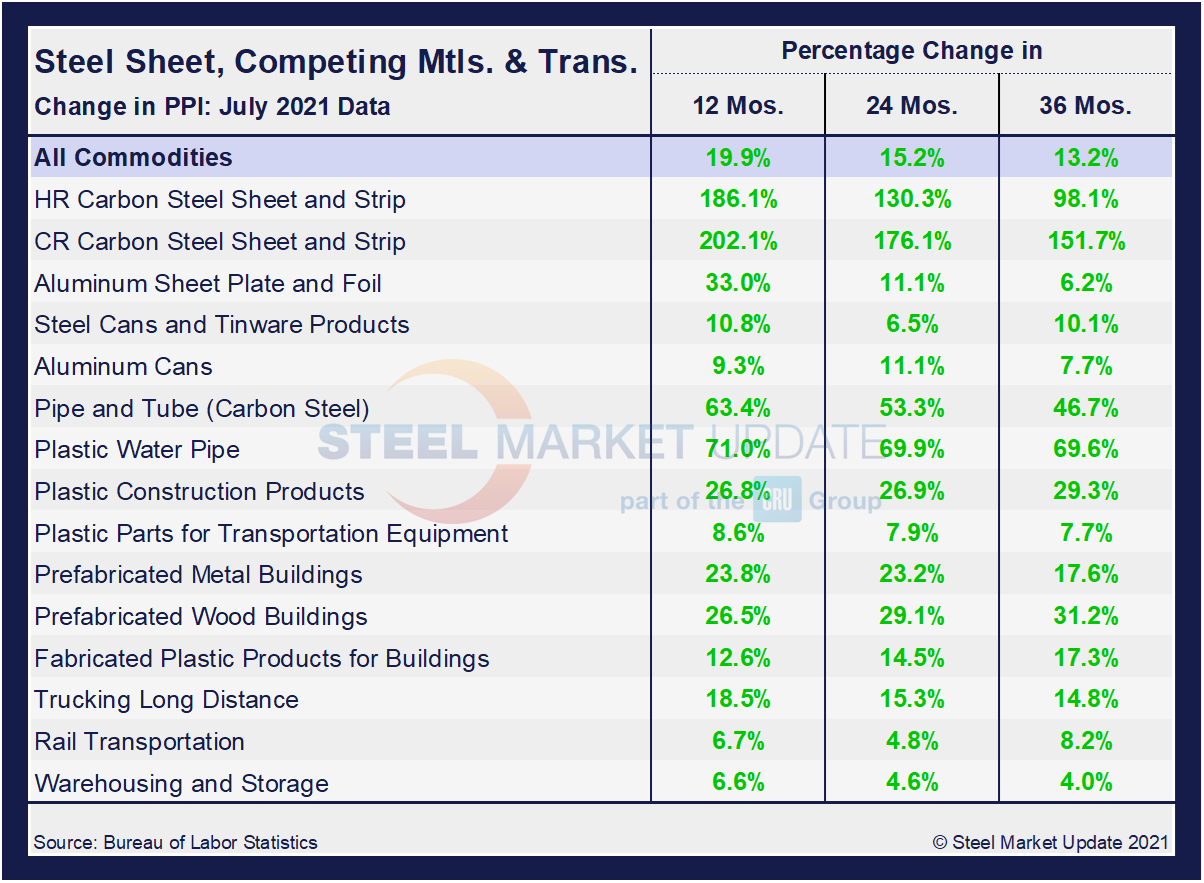

A summary of each segment on a year over one-, two- and three-year basis is shown in the table below. The gain/loss pattern is shown by the color codes; rising prices are considered positive. The positive swing on a 12-month basis would be expected, especially after the initial pandemic-driven slowdown and subsequent rebound. The fact that the table is entirely green at the 24-month and 36-month level, and trending up, is a testament to the historic recovery and growth trajectory for the overall economy. Through July, all 16 sectors are now on the rise at the 12-month level, with HR and CR carbon steel sheet and strip showing huge increases of 186.1% and 202.1%, respectively. The 24-month and 36-month increases are of even greater impact, as they include pre-pandemic periods.

The table includes direct comparisons where possible between steel and competing products, while also including plastic products, transportation, warehousing and storage to further highlight current market conditions. Even though there may not be a direct or specific comparison of steel, these PPI numbers clearly match the trend of rising demand and prices seen across the steel market. Construction-related products are up anywhere from 12.6% to 71.0% at the 12-month level, with similar increases for the 24- and 36-month periods as well. The marketplace has been resilient, surpassing every speculated high as current prospects point towards further gains.

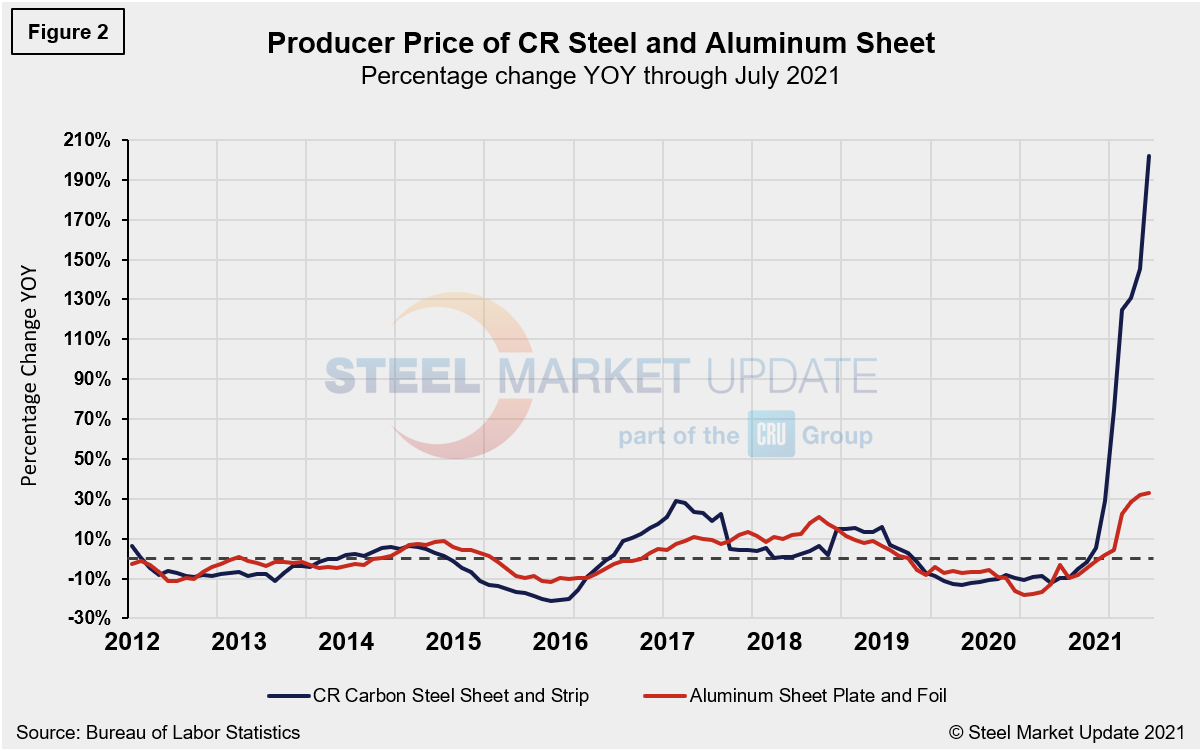

Both steel and aluminum products (Figure 2) have overtaken pre-pandemic PPI figures and reached recent highs. Steel products have shown no real signs of slowing down. Comparing the price changes of cold rolled steel sheet and flat rolled aluminum, the lines have crossed and then reversed only a handful of times over the past five years. Both have rebounded from last year’s losses, however, cold rolled steel sheet prices have reached unheard of levels through July, overshadowing the impressive rebound in flat rolled aluminum.

Cold rolled steel prices reached positive territory in December for the first time since May 2019 and have since jumped by 202.1% through July. Flat rolled aluminum, by comparison, reached a positive 33.0% in July. Cold rolled steel price gains have showed significant growth in July, overtaking hot rolled steel prices in percentage terms. Cold rolled prices surged 22.9% in July versus June, compared to 7.0% for hot rolled prices during the same period.

Although aluminum prices are still well behind steel in terms of growth, they have improved month on month since October when growth was a negative 10.0%. In contrast, steel tinware and aluminum cans have remained largely stable over the past 12 months, as their gains and losses have not been as accentuated. Aluminum cans were up 4.7% month on month in July, and up 8.3% since January. Steel tinware was up 4.9% when compared to June and 10.8% year on year through July.

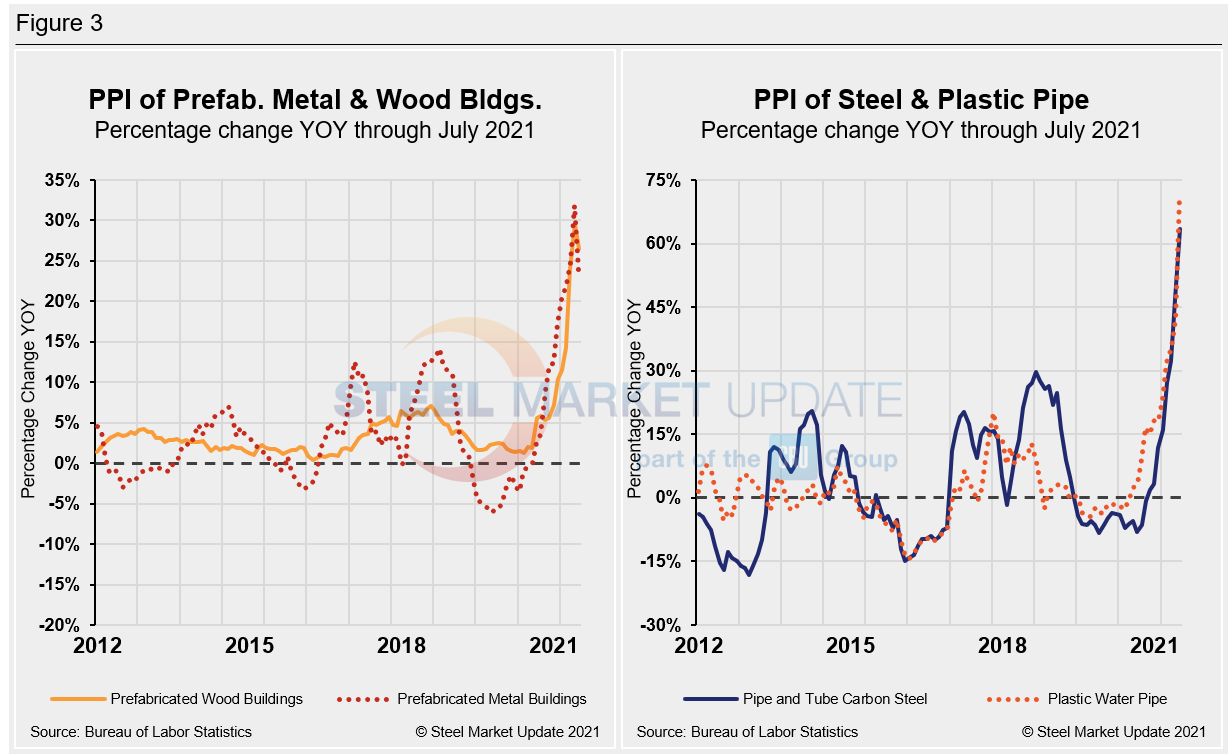

Prices of prefabricated metal buildings and prefabricated wood buildings have both seen significant increases since the beginning of 2021, but showed lack of strength in July. Prefabricated steel building prices fell to a negative 3.5% last June but rallied to a positive 31.8% over 12 months. A similar trend was seen for prefabricated wood buildings over the same period, at 29.5% growth. The positive move turned in July, however, with both producer price categories losing momentum and retreating. Prefabricated metal buildings are currently at a positive 23.8% after falling 6.3% in July. Prefabricated wood buildings dipped 1.6% in July to 26.5% annual growth rate.

The prices of steel and plastic pipe have both experienced big swings due to COVID-19 as well. Steel pipe prices dropped to a negative 8.0% through September last year but rallied to a positive 63.4% through July after an 11.7% jump month on month. By comparison, plastic pipe has rallied by more than 66.4% since September, reaching a positive 71.0% growth in July. Figure 3 is a side-by-side comparison of prefabricated buildings and pipe price dynamics.

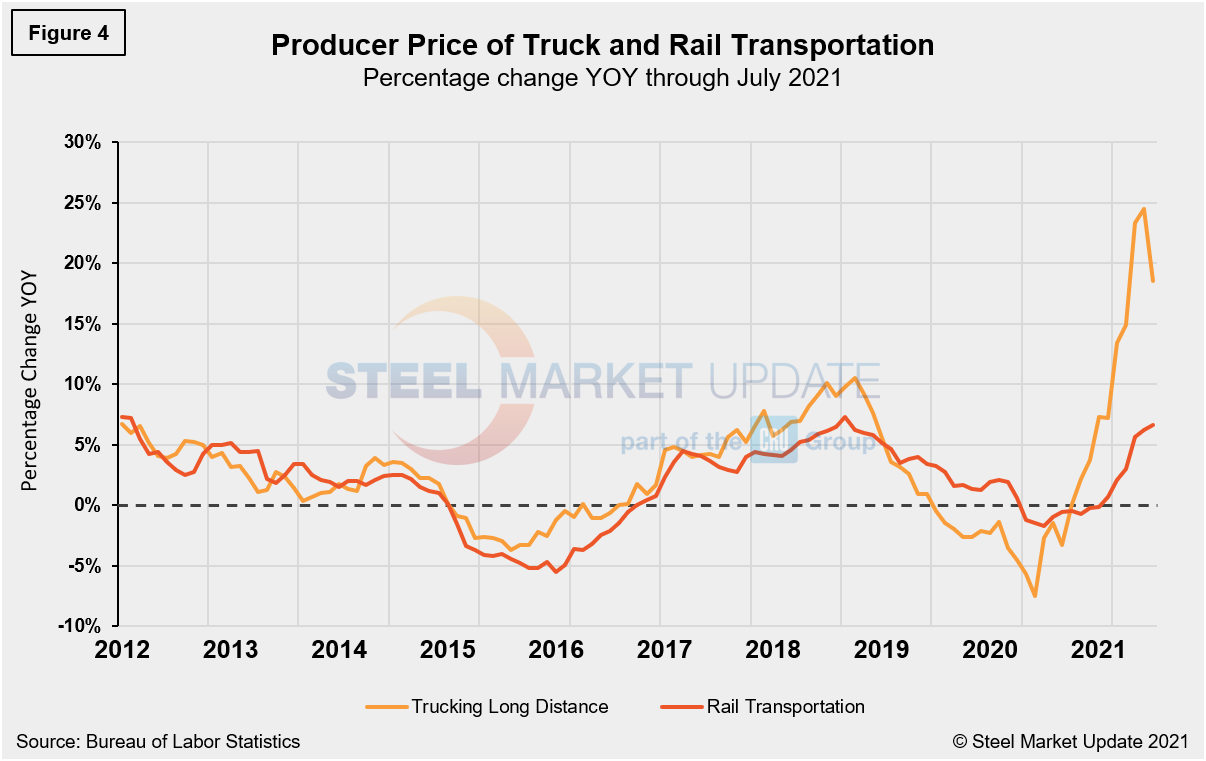

The escalation of truck transportation prices has far exceeded those of rail (Figure 4) since they both bottomed out in June of last year. Rail dipped to a negative 1.5% last June and has since slowly corrected to a positive 6.7% through July 2021. Long distance trucking, on the other hand, recovered to positive 18.5% through July after falling to negative 7.5% one year ago. The increased freight pricing over the past year has been a compounding factor to steel buyers already wrestling with historically high finished steel prices. Even though long-distance trucking decelerated by 0.3% month on month, freight costs have experienced the most significant increase in more than a decade.

Warehousing and storage prices also have rallied. After initially falling to a negative 2.3% at the onset of the global pandemic, they have since rebounded to a positive 6.6% through July, the highest mark since July 2018.

The official description of this program from the BLS reads as follows: “The Producer Price Index (PPI) is a family of indexes that measure the average change over time in the prices received by domestic producers of goods and services. PPIs measure price change from the perspective of the seller. This contrasts with other measures, such as the Consumer Price Index (CPI). CPIs measure price changes from the purchaser’s perspective. Sellers’ and purchasers’ prices can differ due to government subsidies, sales and excise taxes, and distribution costs. More than 10,000 PPIs for individual products and groups of products are released each month. PPIs are available for the products of virtually every industry in the mining and manufacturing sectors of the U.S. economy. New PPIs are gradually being introduced for the products of industries in the construction, trade, finance, and services sectors of the economy. More than 100,000 price quotations per month are organized into three sets of PPIs: (1) stage-of-processing indexes, (2) commodity indexes, and (3) indexes for the net output of industries and their products. The stage-of-processing structure organizes products by class of buyer and degree of fabrication. The commodity structure organizes products by similarity of end use or material composition. The entire output of various industries is sampled to derive price indexes for the net output of industries and their products.

By David Schollaert, David@SteelMarketUpdate.com