Canada

June 4, 2021

Stelco Auto Recycling Initiative to Include EV Batteries

Written by Sandy Williams

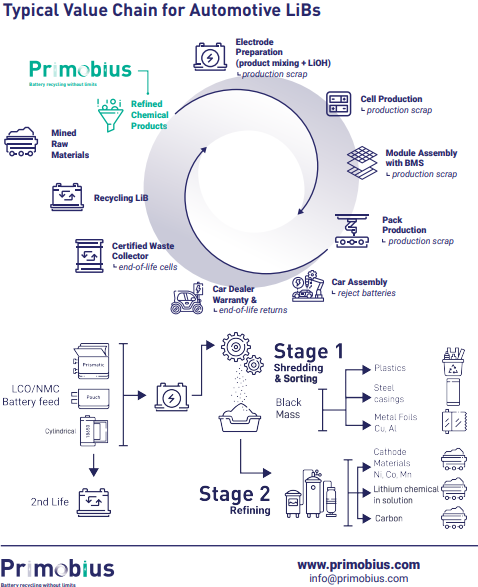

Canadian steel producer Stelco is getting into the electric vehicle battery recycling business. The company announced it will enter into a joint venture with Primobious to build a facility in North America that will recover and recycle materials from EV batteries. Primobious is a 50-50 joint venture of Neometals Ltd and SMS Group, formed to provide recycling solutions for lithium-ion batteries.

In a letter of intent, Stelco and Primobious agreed to equally split the financing for the project. Primobious will supply the recycling plant adjacent to Stelco’s proposed vehicle recycling operation at a to-be-determined location in North America; Stelco will supply sufficient battery feed to the facility. The JV agreement includes plans for expanded capacity as demand for recycled lithium increases.

“Recycling the lithium-ion batteries contained in electric vehicles is a major aspect within this value chain, which will become even more important in the future,” said Primobious in a press release. “Stelco is looking to partner with a party with lithium-ion battery capabilities for the purposes of establishing a battery recycling business in North America as part of its broader automobile recycling pursuits.”

The new facility will be identical to a demonstration plant currently being built by Primobious at the SMS Group site in Germany and will have an annual capacity of 20,000 metric tons.

Another Canadian company, Li-Cycle, was recently awarded a multi-year contract by General Motors to recycle battery scrap from GM’s EV battery manufacturing facility, Ultium Cells. Ultium, located in Lordstown, Ohio, is a joint venture owned by General Motors and LG Energy Solutions that will begin production in 2022.

Currently, there are five mega-sized EV battery facilities in production in North America and more are expected in the coming years. EV batteries are estimated to have an average lifespan of eight to 10 years.

The Biden administration has made electric vehicles and battery recycling part of its infrastructure plan. Many critical minerals required in battery production will be supplied by U.S. allies’ established mines. Extracting critical materials like lithium from expired batteries in the U.S. would reduce the need for imported materials.

“When you look at the way the U.S. has approached the recycling opportunity, what’s very evident is we need to invest in that capacity, we need to take a more proactive approach,” said one administration official. “A big part of the lithium opportunity is really recycling, and being a global leader in recycling the lithium from existing batteries and driving that into these new batteries.”