Market Data

March 29, 2019

PPI Data: Steel Faces Challenge from Competitive Materials

Written by Peter Wright

Producer Price Index data from the Bureau of Labor Statistics shows steel losing ground to rival materials. Steel continues to become less competitive against aluminum, although the rate of change is slowing. In the case of plastic pipe compared to carbon steel pipe, steel is becoming dangerously uncompetitive. Prefabricated metal buildings are still challenged by wood.

This Producer Price Index (PPI) report is intended to provide subscribers with a view of the competitive position of sheet steel, aluminum, plastic and wood. The analysis includes some downstream products and a comparison of truck and rail transportation.

![]() On Tuesday, the BLS released its series of PPIs for more than 10,000 goods and materials through February. For an explanation of this program see the end of this piece. The PPI data are helpful in monitoring price direction and comparison with known transaction prices indicates these indexes are a reasonable representation of the real world, though there may be a lag between the BLS reports and spot prices for steel products. We have also concluded that the actual index values of the PPIs of different products cannot be compared with one another because they are developed by different committees within the BLS. We believe this data is useful in comparing the direction of prices in the short and medium term, but tells us nothing about the absolute value.

On Tuesday, the BLS released its series of PPIs for more than 10,000 goods and materials through February. For an explanation of this program see the end of this piece. The PPI data are helpful in monitoring price direction and comparison with known transaction prices indicates these indexes are a reasonable representation of the real world, though there may be a lag between the BLS reports and spot prices for steel products. We have also concluded that the actual index values of the PPIs of different products cannot be compared with one another because they are developed by different committees within the BLS. We believe this data is useful in comparing the direction of prices in the short and medium term, but tells us nothing about the absolute value.

The headline summary from the BLS was as follows: “The index for final demand goods increased 0.4 percent in February following three consecutive declines. Over 80 percent of the advance can be traced to prices for final demand energy, which rose 1.8 percent. The index for final demand goods less foods and energy edged up 0.1 percent. Conversely, prices for final demand foods fell 0.3 percent.”

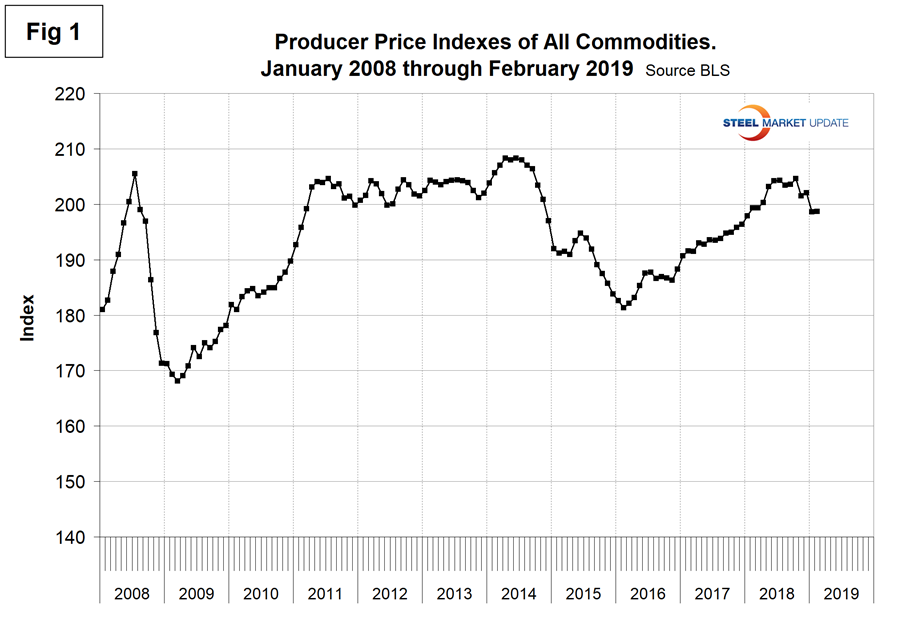

Figure 1 shows the composite PPI of all commodities since January 2008. The index rose steadily for 2½ years through mid-2018 before declining in H2 2018 and stabilizing in the latest February data. Overall, the composite was up by 2.9 percent in the 12 months of 2018 but down by 0.3 percent in February year-over-year.

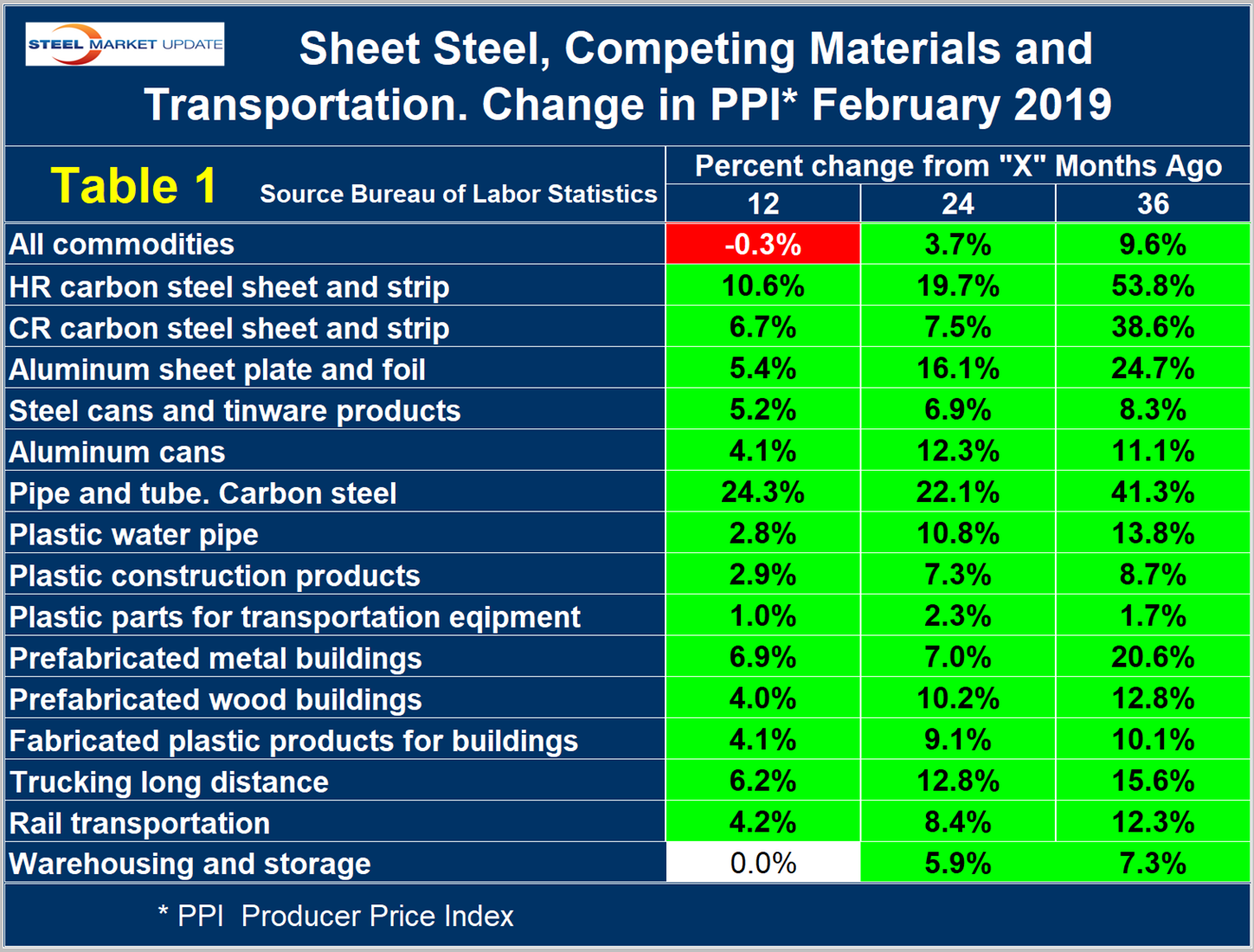

Table 1 is a summary of each segment that we examine on a year over one-, two- and three-year basis. The gain/loss pattern is shown by the color codes; we interpret rising prices as positive. We began this bimonthly analysis in January 2016 and the months June through December 2018 were the first for the whole table to be green. The February table re-introduces red as a year-over-year decline in the composite. The table includes direct comparisons where possible between steel and competing products, also some other plastic products for which there is no direct steel comparison, and a measure of price changes for transportation, warehousing and storage. Some specific comparisons of steel and steel products with their competition are as follows. Please note the Y axis scales are not to the same scale.

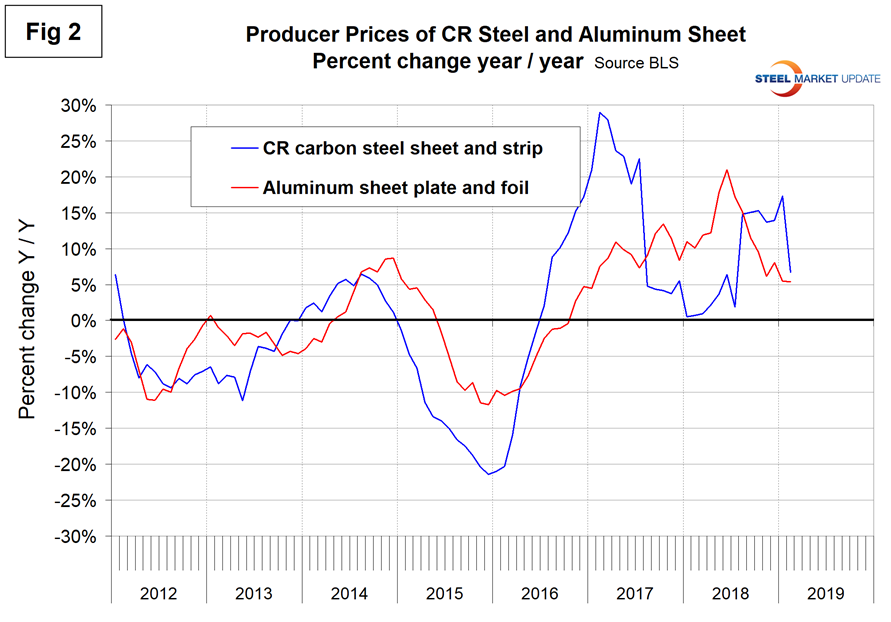

Figure 2 shows the year-over-year comparison of the price change of cold rolled steel sheet and flat rolled aluminum. In the 12 months August 2017 through July 2018, aluminum prices escalated faster than steel. In the second half of 2018 the situation reversed. In February 2019, the rate of change of the price indexes was about the same.

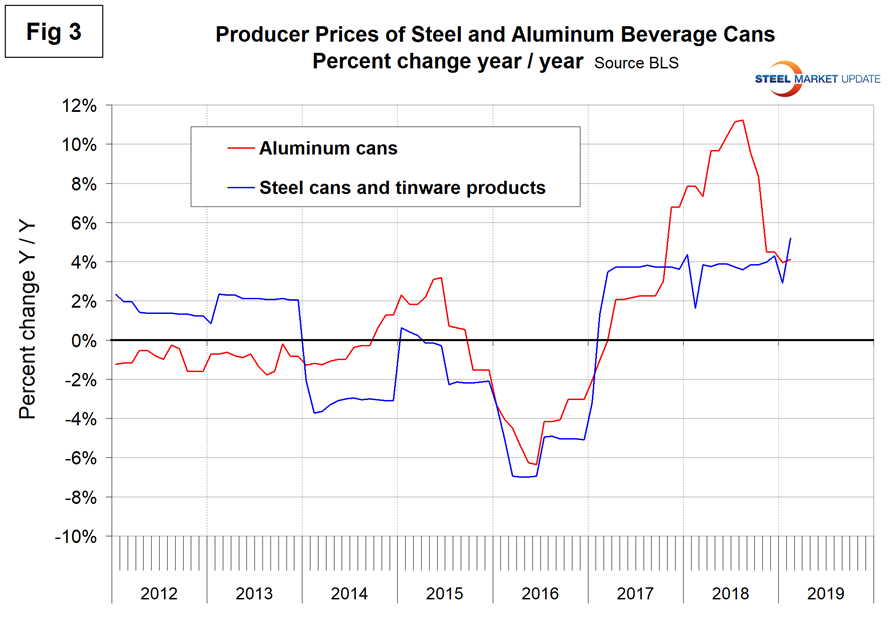

Figure 3 shows the same comparison for steel tinware products and aluminum cans. Aluminum is a much more energy-intensive product than steel and this is reflected in the PPI of both aluminum sheet and aluminum cans. For this reason, the competitive position of aluminum has improved recently to the point that the rate of escalation of the aluminum can index is about the same as steel tinware products.

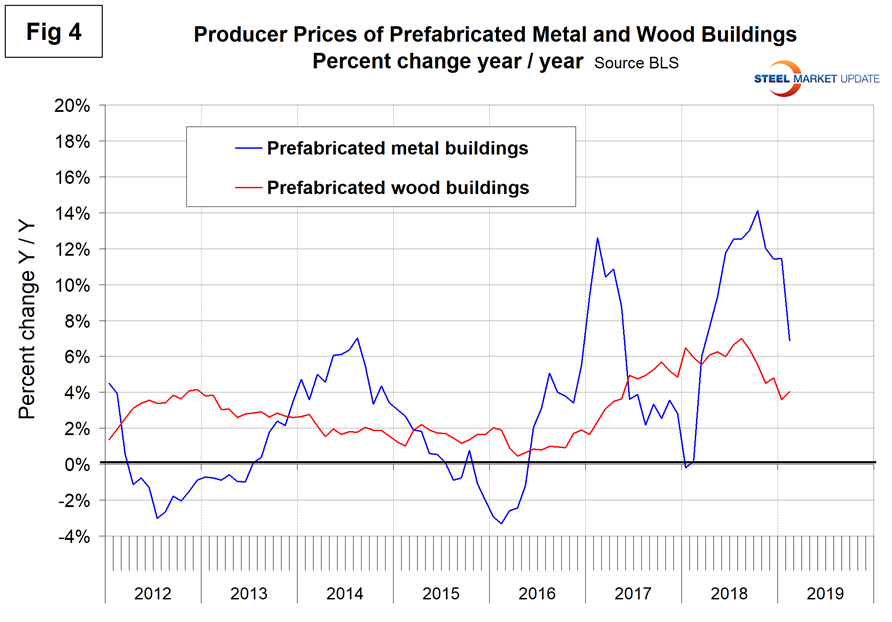

Figure 4 compares prefabricated metal with prefabricated wood buildings. The rate of increase of the price of steel buildings has declined in the last five months but is still higher than wood.

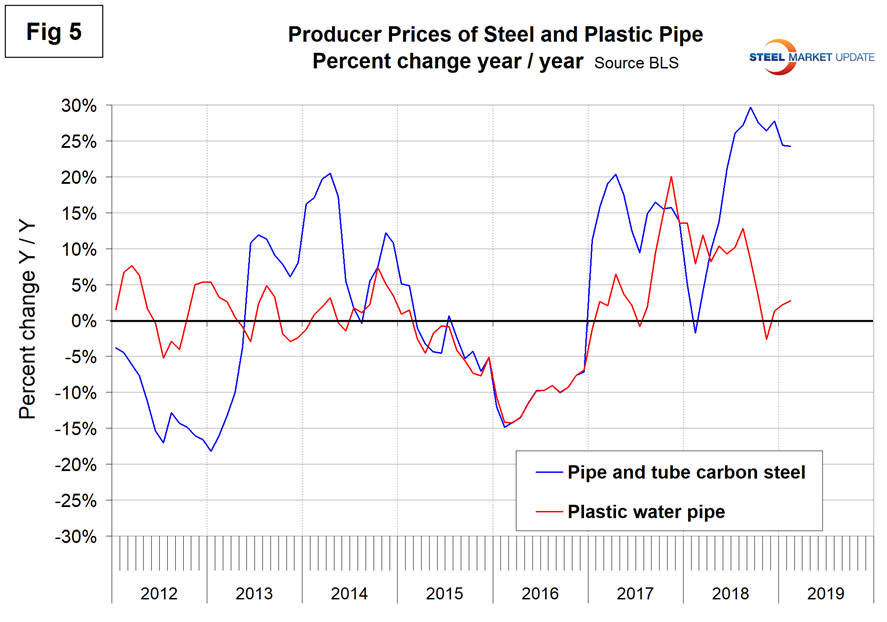

Figure 5 compares the price changes of steel and plastic pipe, which moved in opposite directions to the detriment of steel in 2018. There has been very little correction in the last five months, which suggests that steel’s market share is likely to be eroded in 2019.

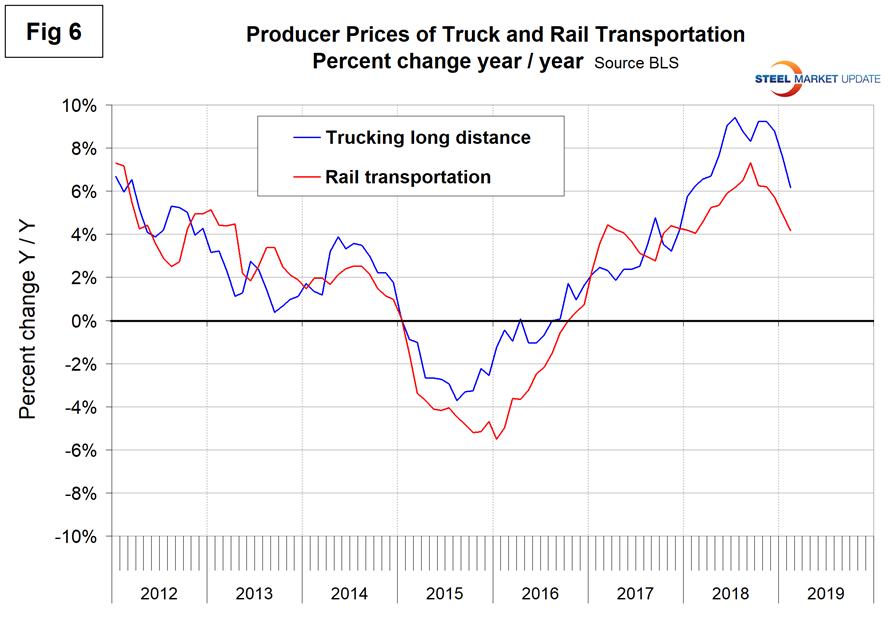

Figure 6 compares the changes in the price of truck and rail transportation. The escalation of trucking prices has exceeded those of rail almost every month since January 2015. Both have declined in the last four months. In February, year-over-year trucking costs were up by 6.2 percent as rail was up by 4.2 percent.

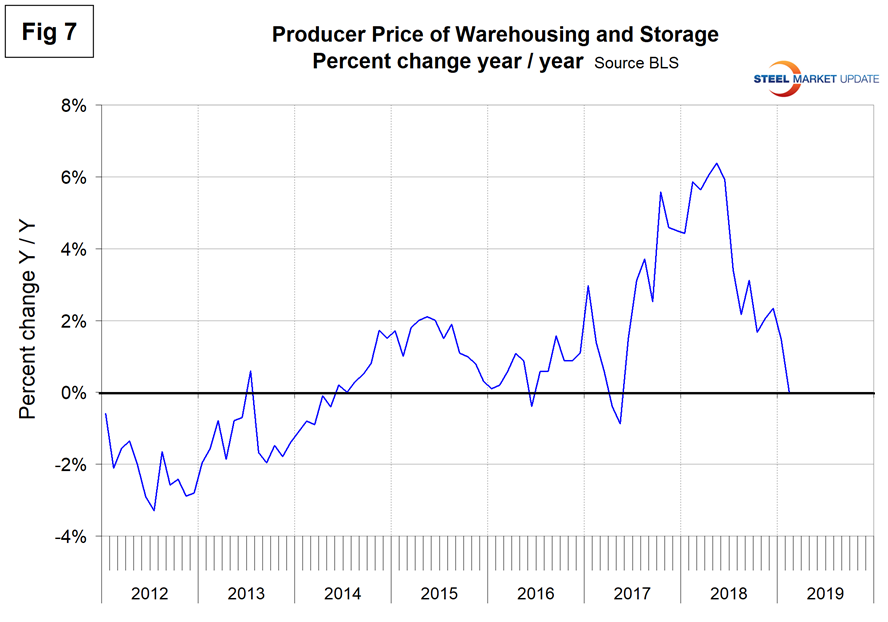

Figure 7 shows that the cost of warehousing and storage has declined steadily since April last year to the point that there was zero increase in February.

The official description of this program from the BLS reads as follows: “The Producer Price Index (PPI) is a family of indexes that measure the average change over time in the prices received by domestic producers of goods and services. PPIs measure price change from the perspective of the seller. This contrasts with other measures, such as the Consumer Price Index (CPI). CPIs measure price change from the purchaser’s perspective. Sellers’ and purchasers’ prices can differ due to government subsidies, sales and excise taxes, and distribution costs. More than 10,000 PPIs for individual products and groups of products are released each month. PPIs are available for the products of virtually every industry in the mining and manufacturing sectors of the U.S. economy. New PPIs are gradually being introduced for the products of industries in the construction, trade, finance, and services sectors of the economy. More than 100,000 price quotations per month are organized into three sets of PPIs: (1) Stage-of-processing indexes, (2) commodity indexes, and (3) indexes for the net output of industries and their products. The stage-of processing structure organizes products by class of buyer and degree of fabrication. The commodity structure organizes products by similarity of end use or material composition. The entire output of various industries is sampled to derive price indexes for the net output of industries and their products.”