Market Segment

December 16, 2018

JSW Ohio Casts First Steel from Reborn EAF

Written by John Packard

There is a “new domestic” steel minimill capable of producing 1.5 million tons per year of steel from scrap. On Friday, JSW USA restarted the electric arc furnace at the JSW Ohio steel plant at Mingo Junction and cast their first domestically produced slab. “The last month has been incredibly butt hard work,” said JSW USA CEO John Hritz. “Now we will be a melt and manufacturer.”

The process of bringing up the 14-year-old EAF after an almost 10-year hiatus was no small feat. Severstal shut the former Wheeling-Pittsburgh Mingo Junction furnace down in February 2009 due to poor business conditions associated with the Great Recession. The furnace was originally going to be brought back online by JSW Ohio in November of this year, but suffered a number of setbacks as various contractors put the finishing touches on the EAF, ladle furnace, caster and surrounding equipment.

JSW advised they anticipate beginning regular production later this week as the company moves toward “120,000 tons per month in a thoughtful way,” said Hritz in a phone interview with Steel Market Update on Saturday. The furnace should be able to produce 1.5 million tons of steel per year.

The hot strip mill at JSW Ohio can produce 3 million tons of hot rolled on an annual basis. Hritz told SMU the company already has “a significant slab inventory from offshore sources.” However, the company’s intention “is to be a 100 percent melt manufacturer” and thus a fully domestic steel producer.

Hritz did not rule out the possibility of buying foreign slabs in the future. Those decisions would be based on “market conditions and our product mix.” He went on to say, “We don’t want to buy slabs that are tariffed,” a reference to the Section 232 tariffs affecting slabs from all but a few countries (like Brazil, which is on a hard quota).

JSW Ohio is planning to add another EAF furnace at Mingo Junction. The combination of the two furnaces would make the mill a 3 million per ton producer.

Earlier in the week, SMU learned that the commercial team is being assembled for the Ohio facility. We were told the plan called for three to four outside salespeople with a field sales director coming under the wing of Senior VP of Sales and Marketing Ernie Rummler. The mill has also been hiring inside sales support as they prepare to build up their tonnage as the EAF ramps up over the coming months to the 120,000 tons per month level CEO Hirtz discussed with SMU over the weekend.

JSW USA has been very active as they prepare to expand their footprint in the United States. The company is constructing a new EAF at their Baytown, Texas, facility, which will allow them to produce plate without having to go to their parent company out of India, as well as Mexico and Brazil, for the required 12-inch slabs. The company broke ground in October on what it claims will be the most technologically advanced electric arc furnace, slab caster and plate mill in the world. It will be the only melt and manufacture plate mill with a contiguous pipe mill in North America.

When SMU saw the JSW USA CEO speak in Chicago at the CRU North American Steel Conference, Hirtz stated, “What have we been doing, what are we doing? We are putting in new equipment and new technology. We are doing something that no one else is doing in America.”

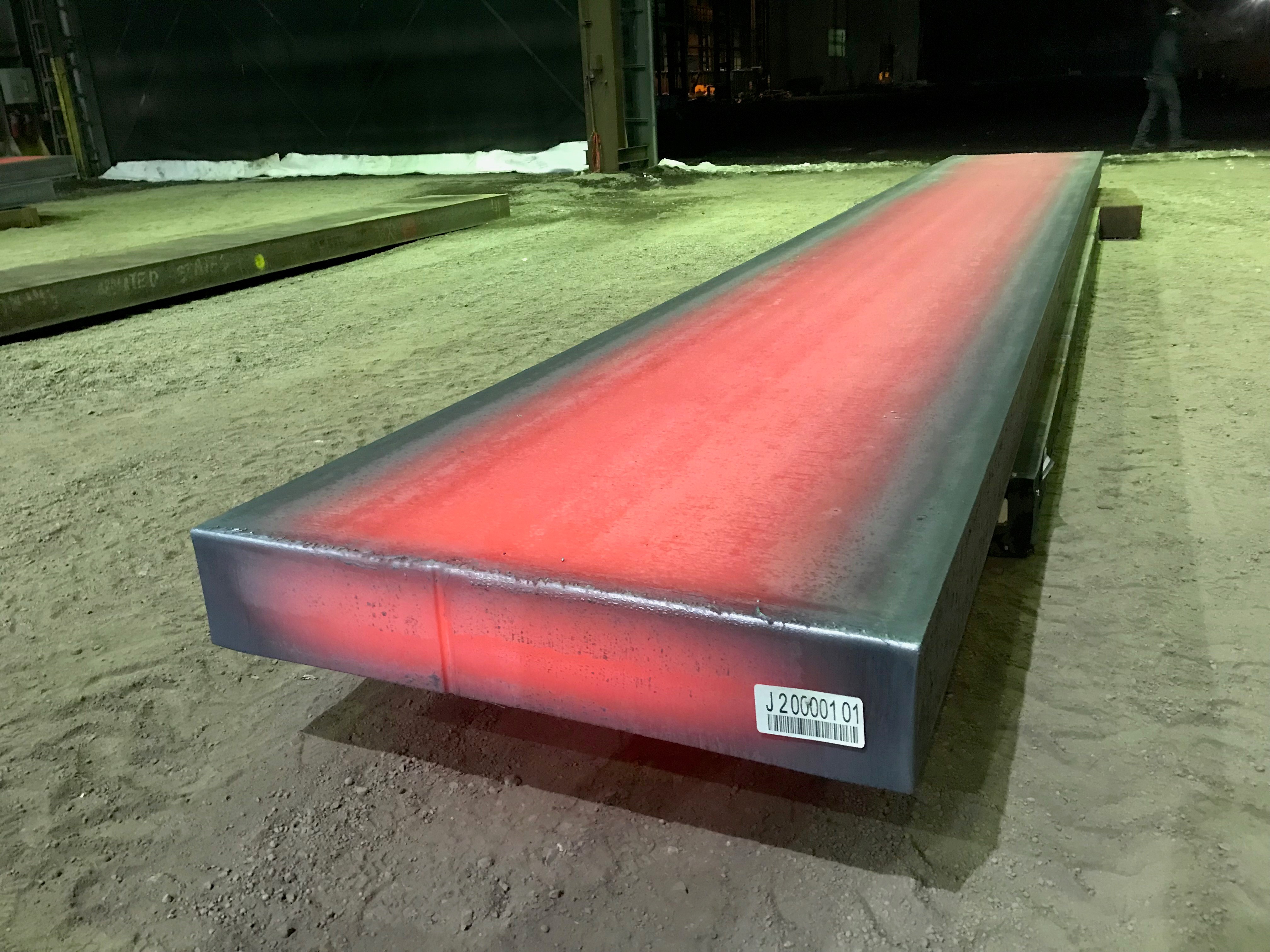

The photographs shown below were taken by JSW USA CEO John Hirtz. The first photo is the first tap of the EAF into a ladle. The second is the first, still red hot, slab produced at JSW Ohio on Friday, Dec. 14, 2018.