Product

May 18, 2018

ArcelorMittal in Virtual Reality

Written by Sandy Williams

Have you ever experienced the dizzying sensation of vertigo? Perhaps you were on a Steel Market Update workshop tour and felt woozy as you ascended higher and higher on the catwalks during the mill tour.

ArcelorMittal South Africa recognized the danger that a fear of heights could cause employees who work in extreme conditions and at great heights and decided to do something about it. The company contracted with game developer Sea Monster to create a virtual reality environment modeled on its Vanderbijlpark plant.

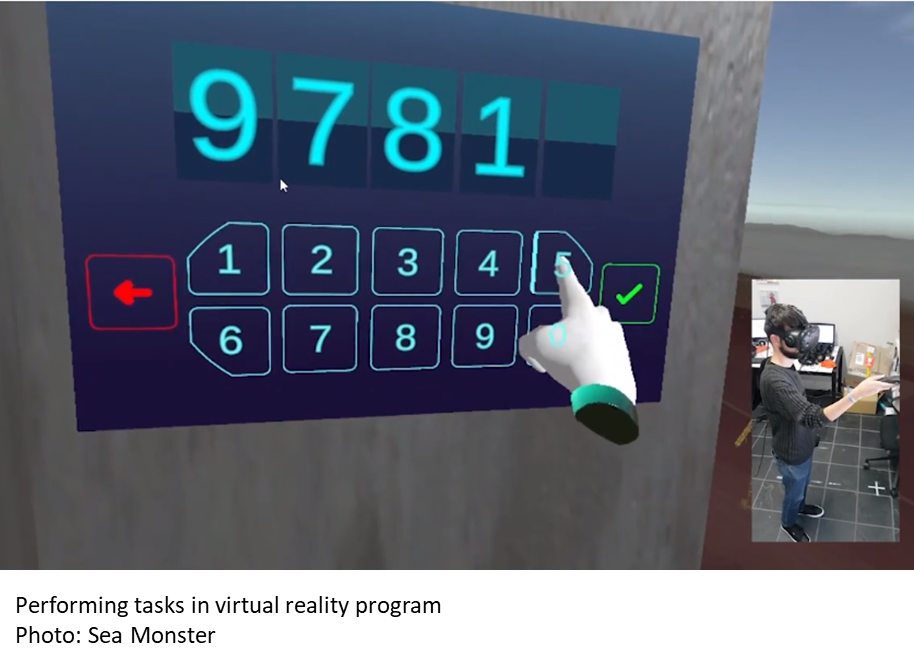

Named the Blast Furnace Experience, it allows trainees to be immersed in a realistic simulation where they ascend a lift to a height of 190 meters and are asked to perform a series of cognitive tasks. To make the experience as real as possible, fans were placed to simulate wind, as well as a moving platform to simulate the movement of the lift.

After allowing time for trainees to become accustomed to virtual reality on the ground floor, they are moved on to the lift. Instructors monitor trainee heart rate to determine possible fear of heights, as well as to check for signs of nausea or dizziness. Trainers from LRMG Performance Agency and ArcelorMittal are with trainees every step of the way to evaluate performance and offer support if fears become apparent.

If the trainee completes the three tasks accurately and within the allotted time, they move on to further training at the company. If a fear of heights is exhibited, they are reassigned to different duties within ArcelorMittal South Africa.

ArcelorMittal began using the program in January and, so far, eight of 400 trainees exhibited a crippling fear of heights. ArcelorMittal says the $160,000 investment in the program is well worth it in terms of employee safety and cost to the company in the event of a fatality. ArcelorMittal has shown interest in expanding the program to its other plants around the world.

Sea Monster said it developed the animated world rather than a 360 degree camera shoot so that the experience could be interactive. Attention was paid to detail, even including visual perspective on cars and buildings as trainees ascend the virtual reality lift.

So far, the project has been successful. “It is a technology that we need to evaluate very cautiously, and we need to embrace a scientific process to do so, but obviously in a creative context,” said Glenn Gillis of Sea Monster.