Market Segment

November 21, 2017

MSCI: October Shipments Top Expectations

Written by Peter Wright

Service center shipments in October exceeded expectations, led by long products and plate, according to Steel Market Update’s analysis of Metals Service Center Institute data.

Daily shipments in October were 1.9 percent higher than in September. On average since 2009, October has decreased by 1.9 percent, therefore these latest numbers were better than the historical norm for this time of year. Carbon steel shipments were 144,900 tons per day in October and days on hand on the 31st were 49.1, which was down from 50.6 at the end of September, 50.4 at the end of August and 50.3 at the end of July. In this analysis, we began to report days on hand for the first time in August. All previous SMU updates reported months on hand. The problem with MoH is that it is influenced by the number of shipping days, therefore another variable is introduced. In months with a high number of shipping days, monthly shipments are elevated, which reduces the numerical value of inventory divided by shipments. In months with few shipping days, the reverse is the case. This is a big deal because shipping days can be as low as 18 and as high as 23. This variable is eliminated by considering inventory divided by daily shipments.

Intake and Shipments

In October, total carbon steel intake at 143,900 tons per day was down from 149.0 in September and was 3,300 tons less than shipments. This was the first month of deficit after four months of surplus. Total sheet products had an intake deficit of 3,200 tons. Plate was the only product with an intake surplus.

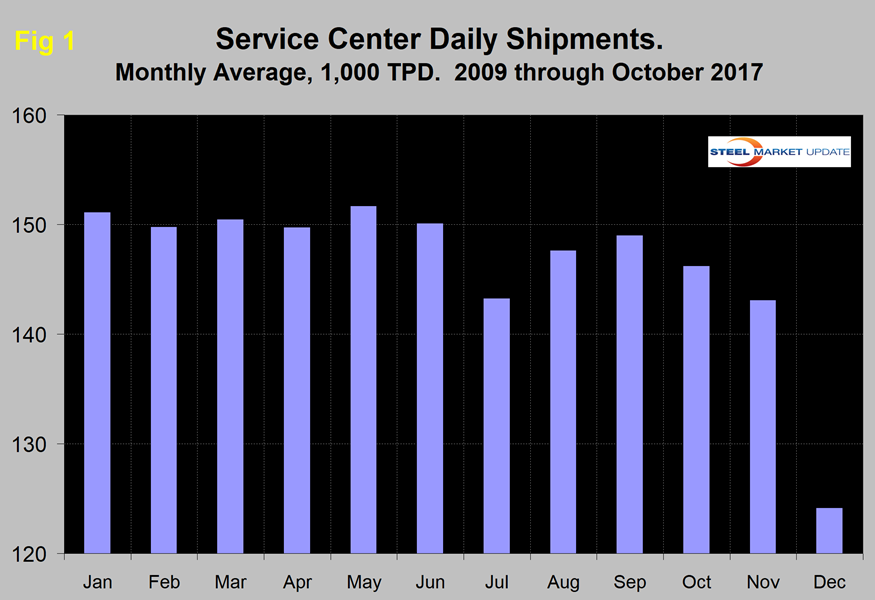

Total daily carbon steel shipments increased from 144,400 tons in September to 147,200 tons in October. MSCI data is quite seasonal, and we need to eliminate that effect before commenting in detail on an individual month’s result. Figure 1 demonstrates this seasonality and why comparing a month’s performance with the previous month can be misleading, particularly in July and the fourth quarter of the year. We can expect shipments to decrease in the final two months of the year. In the commentary below, we report year-over-year changes to eliminate seasonality and provide an undistorted view of market direction.

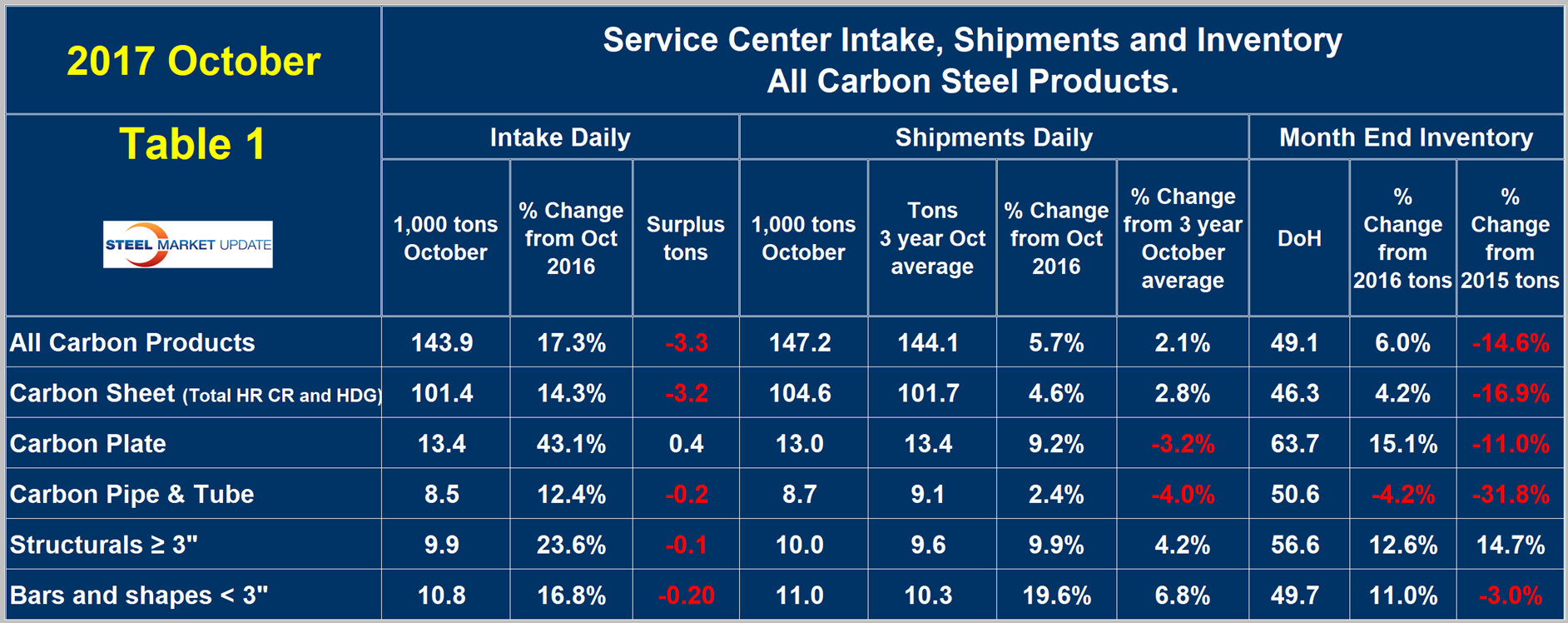

Table 1 shows the performance by product in October compared to the same month last year, and also the average daily shipments for this and the two previous months of October. We then calculate the percent change between October 2017 and October 2016 and compare it to the most recent three-year October average. October this year was up by 5.7 percent from October 2016 and up by 2.1 percent from the three-year October average. The fact that the year-over-year growth comparison is better than the three-year comparison suggests that momentum is positive, and indeed we now have five straight months where the year-over-year change has improved. Shipments of all individual products were up from October last year.

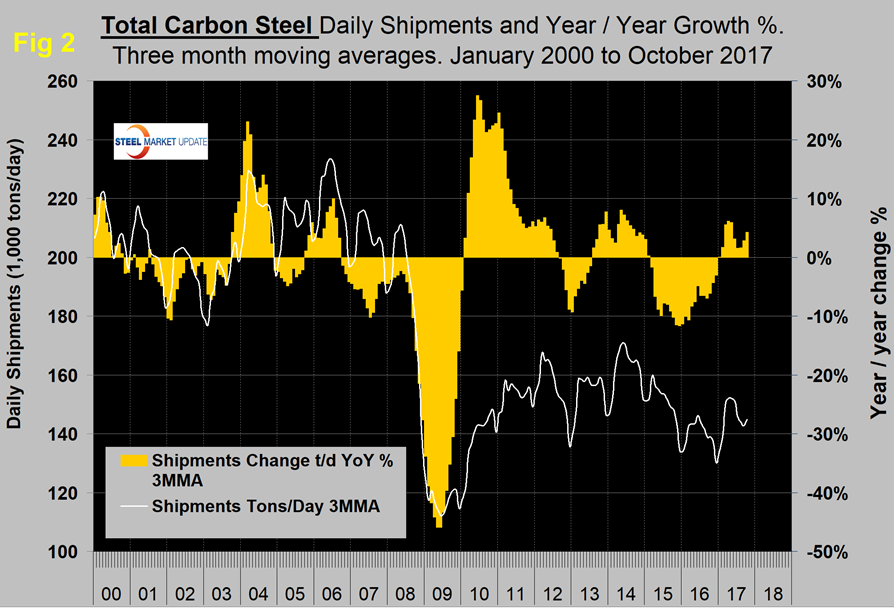

Figure 2 shows the long-term trend of daily carbon steel shipments since 2000 as three-month moving averages. (In our opinion, the quickest way to size up the market is the brown bars in Figures 2, 3, 4, 5 and 6, which show the percentage year-over-year change in shipments by product.) In January, on a 3MMA basis, there was positive year-over-year growth of 0.07 percent, which improved to 6.2 percent in April before declining to positive 1.58 percent in July and recovering to 4.27 percent in October. These were the first positive year-over-year results since February 2015.

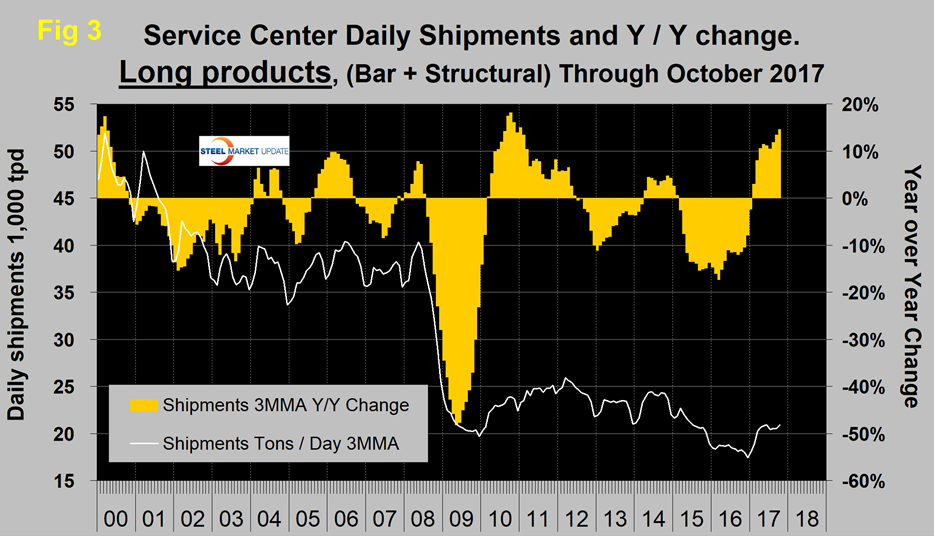

Figure 3 shows monthly long product shipments from service centers as a 3MMA with year-over-year change. Growth has improved this year and is now the highest it has been since late 2010. The seven months through October all exceeded a 10 percent year-over-year growth rate on a 3MMA basis, and in the latest data growth was 14.6 percent.

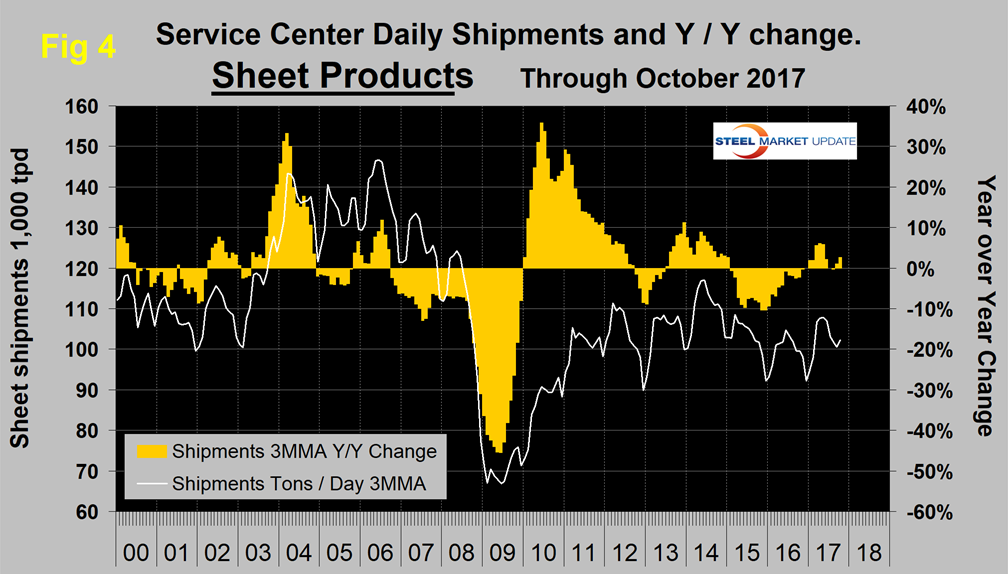

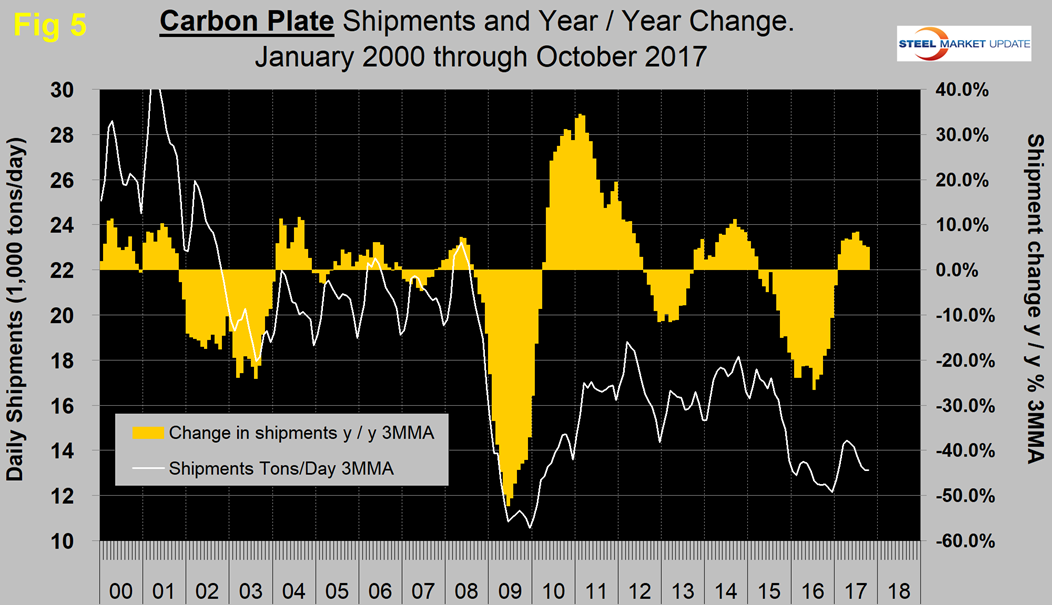

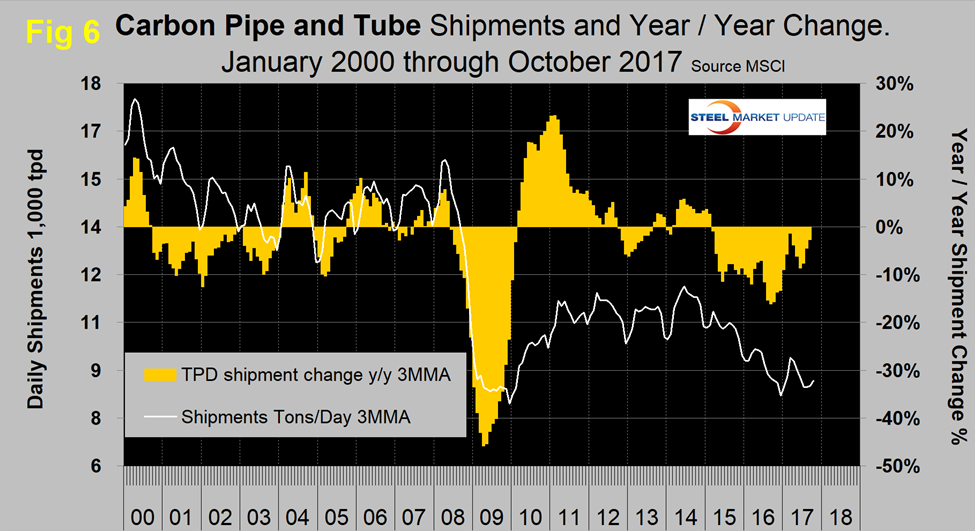

Figures 4, 5 and 6 show the 3MMA of daily shipments and the year-over-year growth for sheet, plate and tubular goods, respectively. Plate performed much worse than sheet in 2015 and 2016. This year plate has begun to close the gap. Pipe and tube have performed very poorly since early 2015, which coincided with the decline in rig count. The rig count has doubled from where it was this time last year, but so far this has not translated into improved shipments of pipe and tube from service centers.

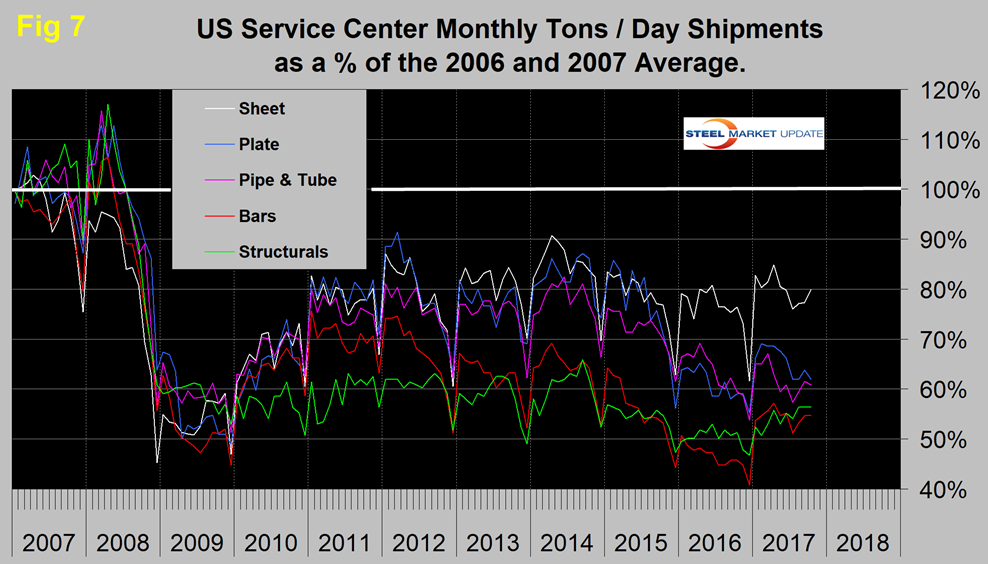

In 2006 and 2007, the mills and service centers were operating at maximum capacity. Figure 7 takes the monthly shipments by product and indexes them to the average for 2006 and 2007 in order to measure the extent to which shipments of each product have recovered. Each year, all products experience the December collapse and January pickup. In October, the total of carbon steel products was 69.3 percent of the average monthly shipping rate that occurred in 2006 and 2007. Structurals and bar were 56.3 percent and 54.7 percent, respectively. Sheet was at 79.9 percent, plate at 61.9 percent and tubulars at 60.8 percent.

Inventories

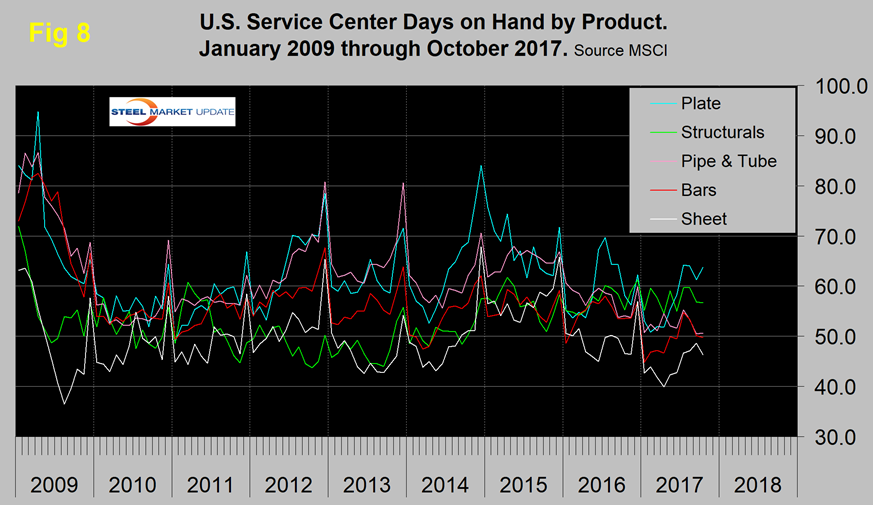

March closed with months on hand, (MoH) of 1.94 for all carbon steel products, which was the lowest level in 13 years (since August 2004). This anomaly partly resulted from 23 shipping days, which is the maximum that ever occurs. We have now removed that effect as described above. Compared to the end of October last year, total carbon steel inventories were up slightly from 49.0 to 49.1 days on hand (DoH). On a tonnage basis, total carbon steel inventories at the end of October were up by 6.0 percent year over year, but down by 14.6 percent compared to the end of October 2015. Compared to 2016, all products except tubular goods had an inventory tonnage increase. Figure 8 shows the DoH by product monthly since October 2009.

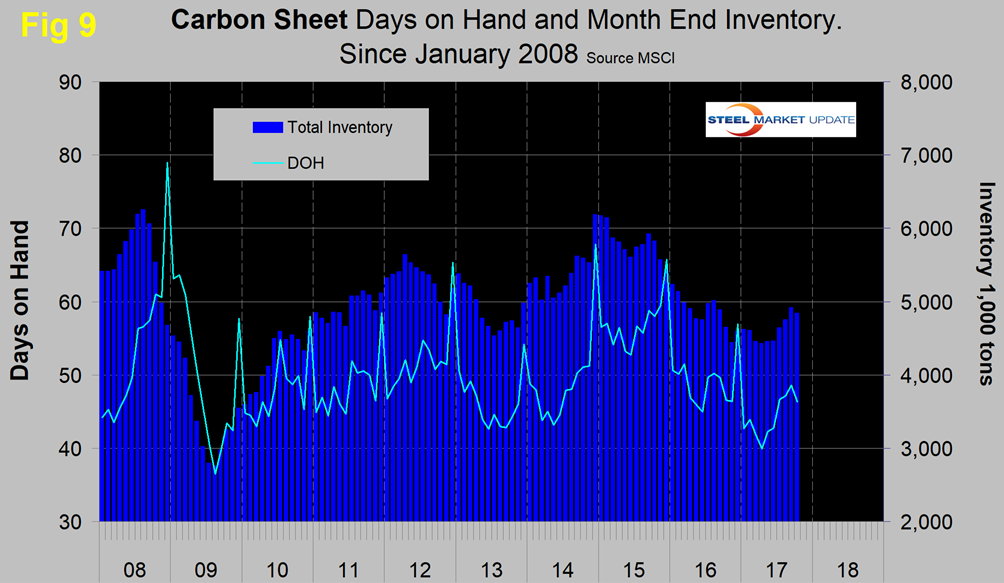

Figure 9 shows both the month end inventory and days on hand since October 2008 for total sheet products. In the last three years, both the year end spikes and the mid-year troughs of sheet inventory tonnage have been declining.

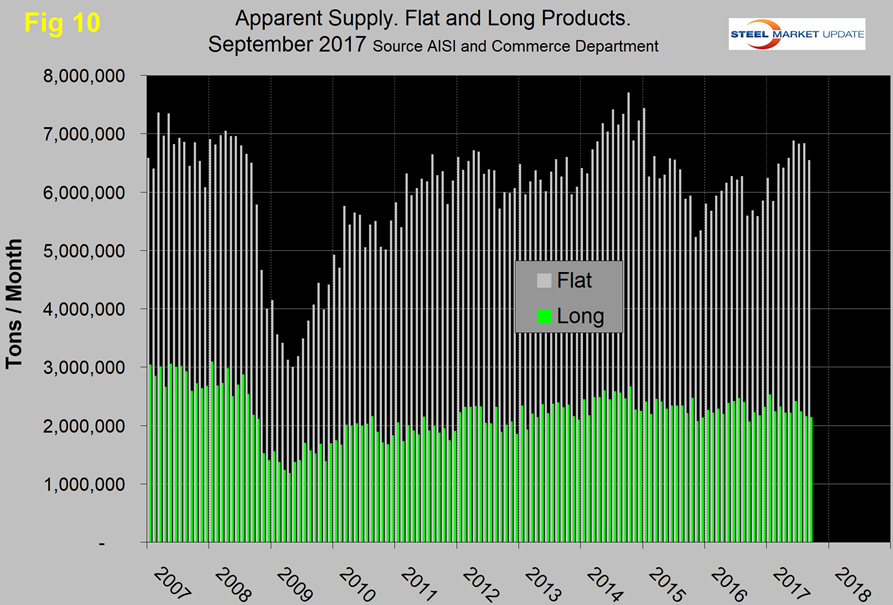

SMU Comment: In Figures 2, 3, 4, 5 and 6, the white lines show tons per day shipments on a 3MMA basis. In the first few months of 2017, there was the normal seasonal increase in total shipments as December moved out of the rolling three-month picture. However, there has been a big difference between products. Long products have enjoyed double-digit growth in the last seven months, but at the other extreme tubulars have contracted every month for almost three years. Plate has had quite strong growth this year and has performed much more robustly than sheet, which had slightly negative year-over-year growth in both June and July. These observations don’t jibe with our analysis of AISI and Commerce Department data. Figure 10 shows the total supply to the market of long and flat products based on AISI shipment and import data through September, which is the latest data available.

Total supply of long products has gone nowhere since mid-2014 in contrast to the recent double-digit growth at the service center level. Flat rolled products on the other hand declined in September, but even so have had very strong growth in total supply to the market for the last 12 months. At the service center level, sheet products haven’t done much this year, though plate with its much smaller volume has fared better. There is also a discrepancy between total supply to the market and service center shipments of tubular goods. The total supply of tubulars is up sharply this year, according to AISI and the Commerce Department, but service center year-over-year shipments have been in decline since February 2015.

The SMU database contains many more product-specific charts than can be shown in this brief review. For each product, we have 10-year charts for shipments, intake, inventory tonnage and months on hand. Some readers have requested these extra charts for particular products and others are welcome to do so.