Market Segment

December 14, 2015

Service Center Intake, Shipments and Inventory through November 2015

Written by Peter Wright

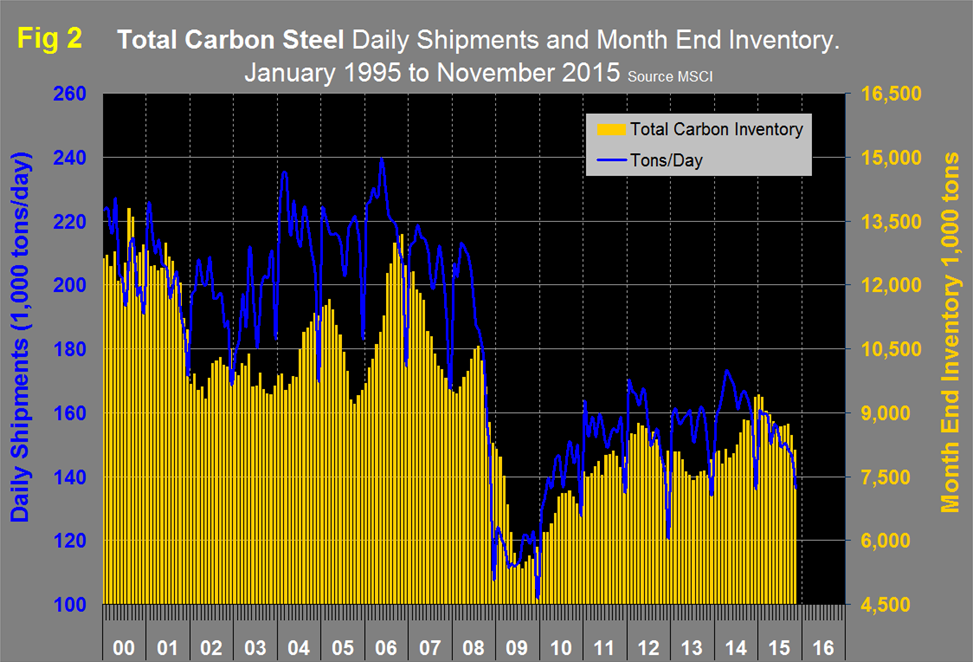

Based on Steel Market Update (SMU) analysis of the recently released MSCI service center inventory and shipment data, total service center carbon steel shipments decreased by 482,000 tons in November to 2.728 million tons. Shipping days at 20, were down by two from October. On a tons per day basis (t/d) shipments decreased from 145,900 tons in October to 136,400 tons in November.

![]()

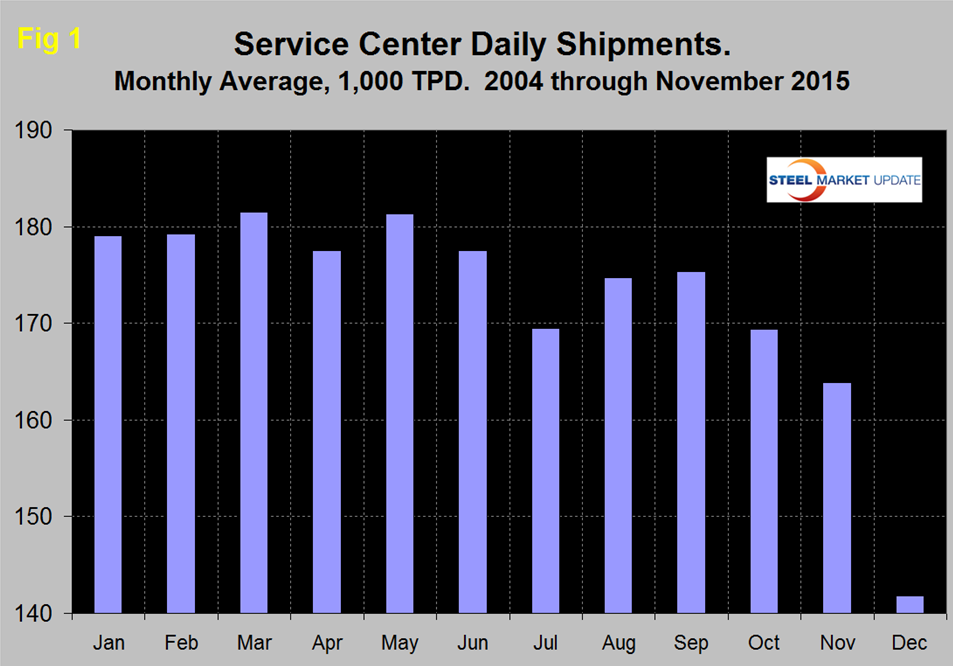

In the twelve years since 2004 November shipments on average have been down by 3.3 percent from October, this year shipments were down by 6.5 percent. Therefore on a long term basis (12 years) the November performance compared to October was worse than normal. This observation is only intended to give a long term perspective because MSCI data is extremely seasonal and we need to get past that before commenting in detail on current results. Figure 1 demonstrates this seasonality and why comparing a month’s performance with the previous month is usually misleading.

We are now in a period when shipments in t/d will decrease for three straight months before bouncing back in January. In the SMU analysis we always consider year over year changes to eliminate seasonality. Table 1 shows the performance by product in November compared to the same month last year and also with the average t/d shipments for November in the last three years.

We then calculate the percent change between November 2015 and November 2014 and with the 3 year November average. Our intention is to provide an undistorted view of market direction. In November intake at 119,100 t/d was 17,300 tons less than shipments. This was the second month of deficit after three straight months of surplus. The intake deficit was evident for all product groups except structurals. Compared to last November, intake was down by 18.57 percent overall and all product groups were down by double digits.

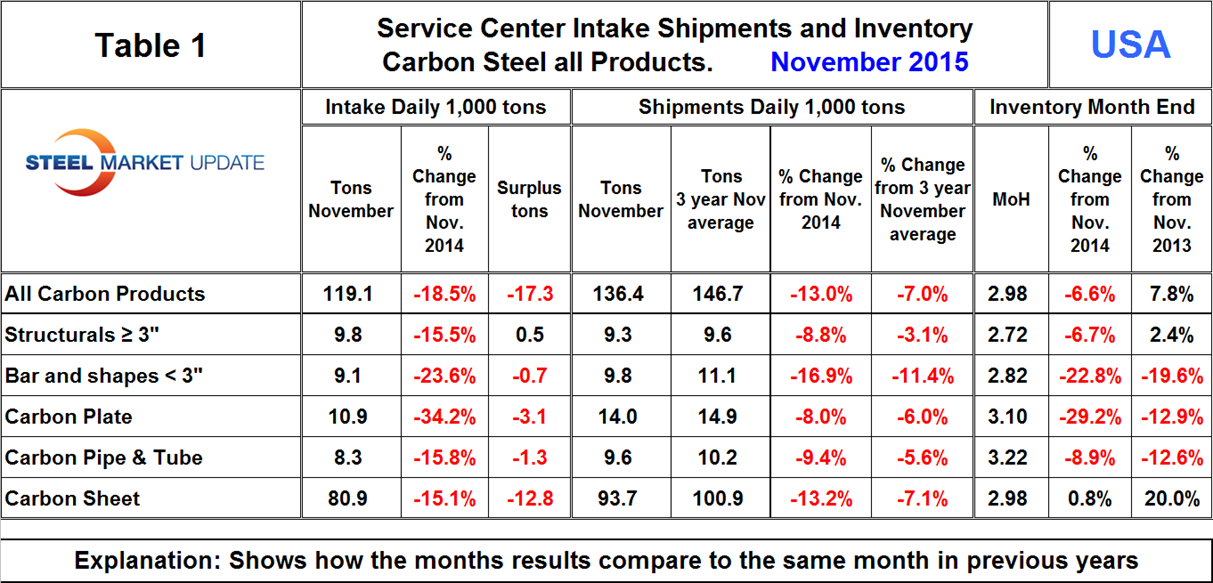

Shipments of all products on a t/d basis were down by 13.0 percent from November last year and were 7.0 percent less than the average November shipments for 2015, 2014 and 2013. The fact that the single month y/y growth comparison is worse than the three year comparison is an indication that momentum is negative and the contraction is accelerating. Figure 2 shows the long term trends of daily shipments and month end inventory since 2000.

Daily shipments had a post recessionary high of 173,300 in April last year and have had a downward trend ever since. In November shipments of all products except sheet and tubulars were down by a minimum of 8.0 percent year over year. Bars + light shapes and sheet had the highest rate of shipment contraction.

November closed with months on hand (MoH) of 2.98, up from 2.64 at the end of October. All products except sheet had a y/y decrease in MoH. Figure 3 shows the MoH by product monthly since January 2009.

Plate is now back in line following extremely high inventory levels at the end of last year.

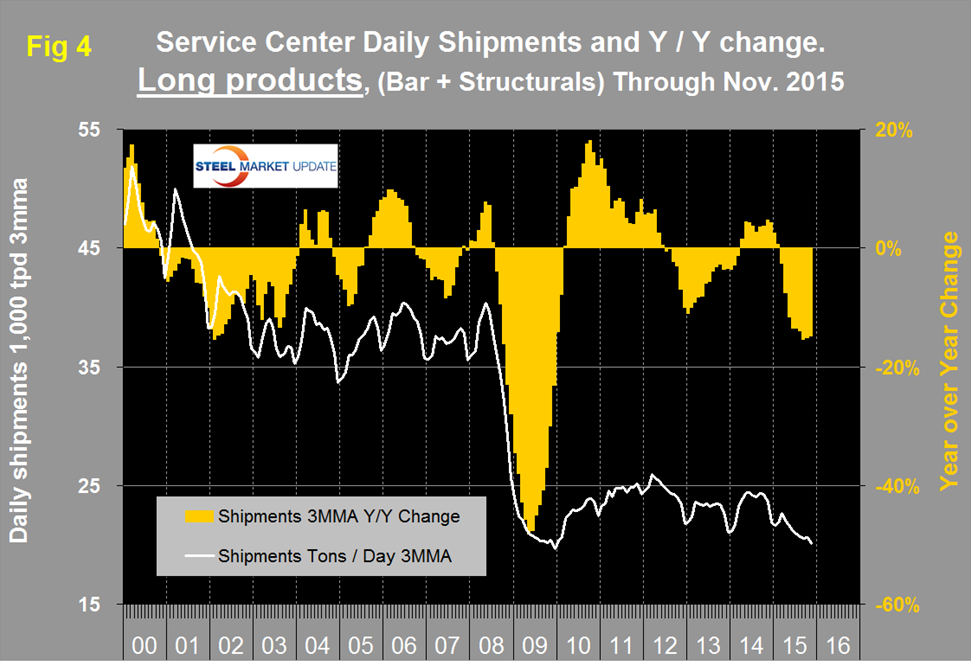

There continues to be a wide difference between the performances of flat rolled (sheet + plate) and long products (structurals + bar) at the service center level. Long products have had a very poor recovery from the recession. On a 3MMA basis y/y, the growth of long product shipments was negative for 21 straight months until April last year which was the first of eleven months of growth. However in March on a y/y basis shipment growth returned to negative territory and has stayed there ever since with double digit contraction for each of the last seven months (Figure 4).

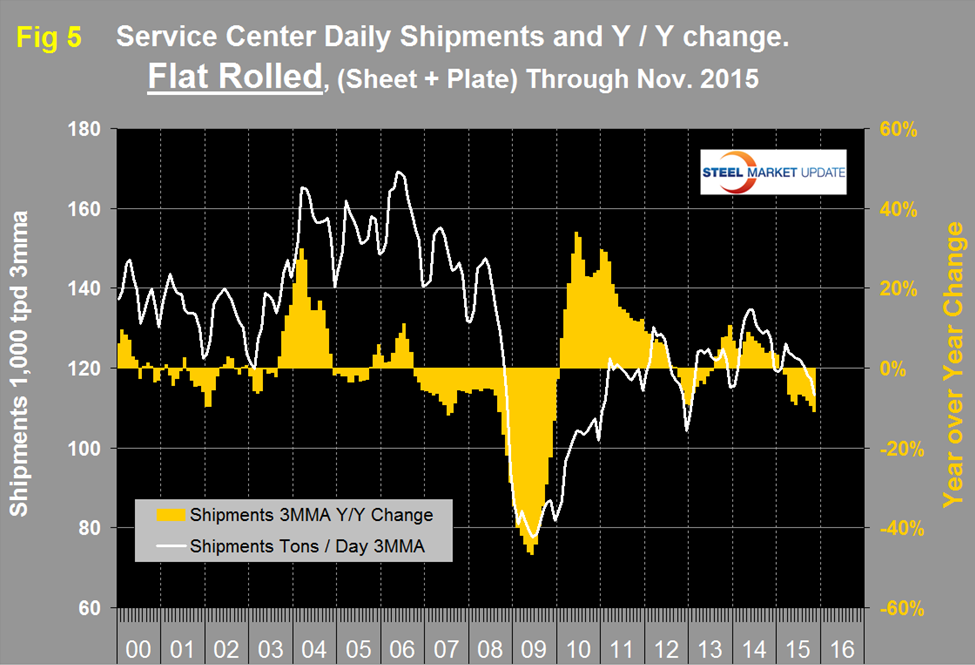

Considering the improving construction statistics, we have no explanation for this dismal and deteriorating long product performance other than that possibly more customers are bypassing service centers and buying direct from mill inventories. Flat rolled has had a much better recovery since mid-2009 and had positive y/y growth for 18 straight months through January this year. In February growth slowed to zero, in March came in at negative 1.6 percent and has been negative ever since (Figure 5).

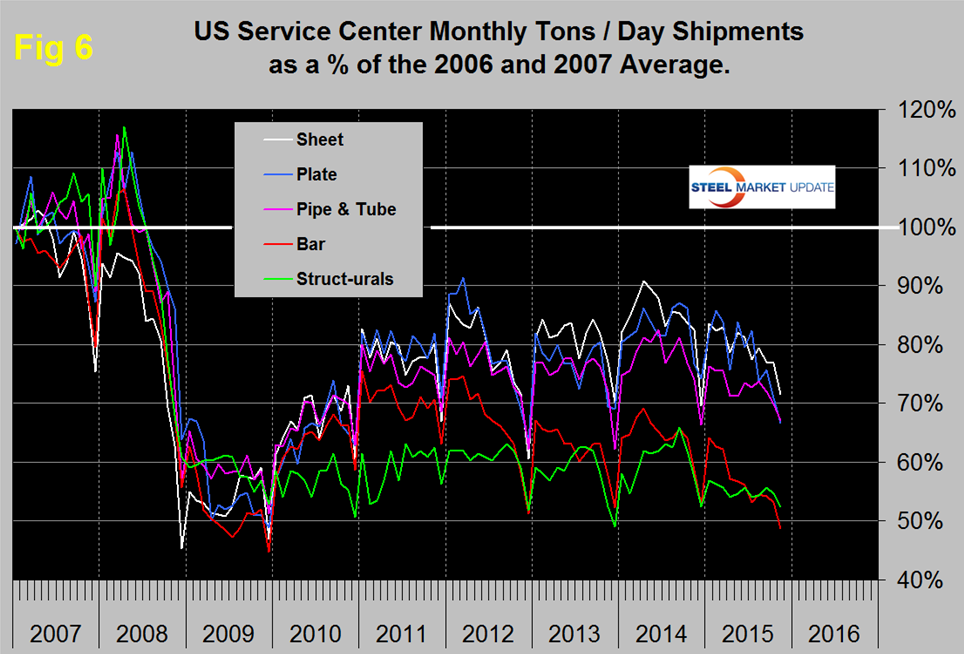

In 2006 and 2007, the mills and service centers were operating at maximum capacity. Figure 6 takes the shipments by product since that time frame and indexes them to the average for 2006 and 2007 in order to measure the extent to which service center shipments of each product have recovered.

Again it can be seen that bar and structurals have the worst record and that bars + light shapes have suffered a major deterioration this year. Sheet, plate and tubulars are now showing a deteriorating trend since mid-year. The total of carbon steel products is now at 66.2 percent of the shipping rate that existed in 2006 and 2007, with structurals and bar at 52.4 percent and 48.8 percent respectively. Sheet is at 71.6 percent, plate at 66.7 percent and tubulars at 67.1 percent.

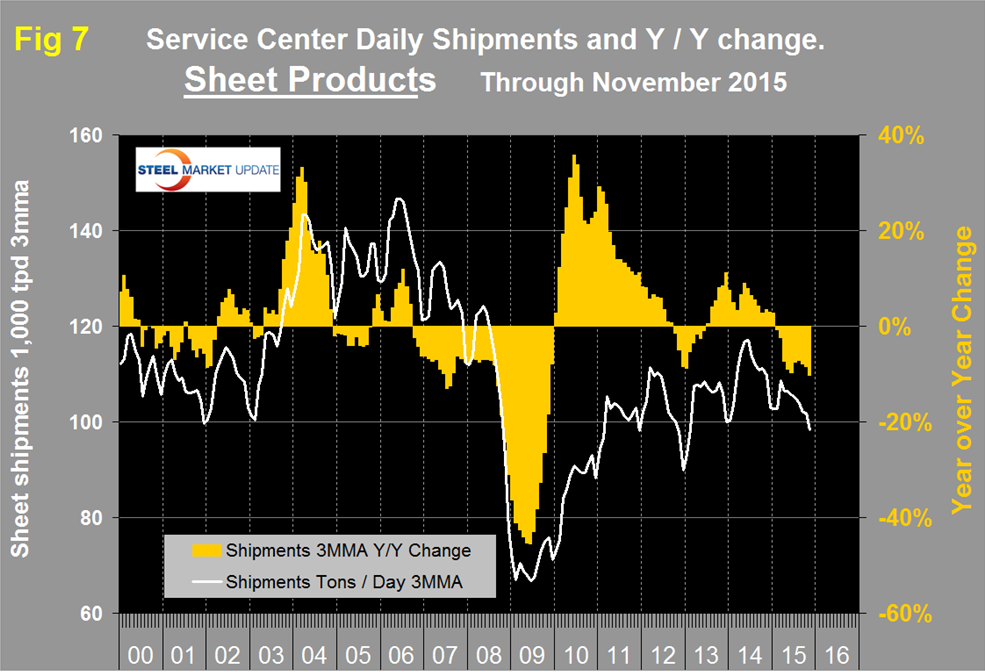

MSCI uses product nomenclature flat and plate. In this analysis at SMU we replace the term flat with sheet. By our interpretation of the MSCI’s data their definition of “flat” is all hot rolled, cold rolled and coated sheet products. Since most of our readers are sheet oriented we have removed plate from Figure 5 to highlight the history of sheet products which are shown in (Figure 7).

Following the strong post-recession recovery, sheet products experienced 9 months of decline from November 2012 through June 2013. This was followed by 18 months of growth through January this year but February slipped back into negative territory at -0.7 percent year over year and has been negative ever since.

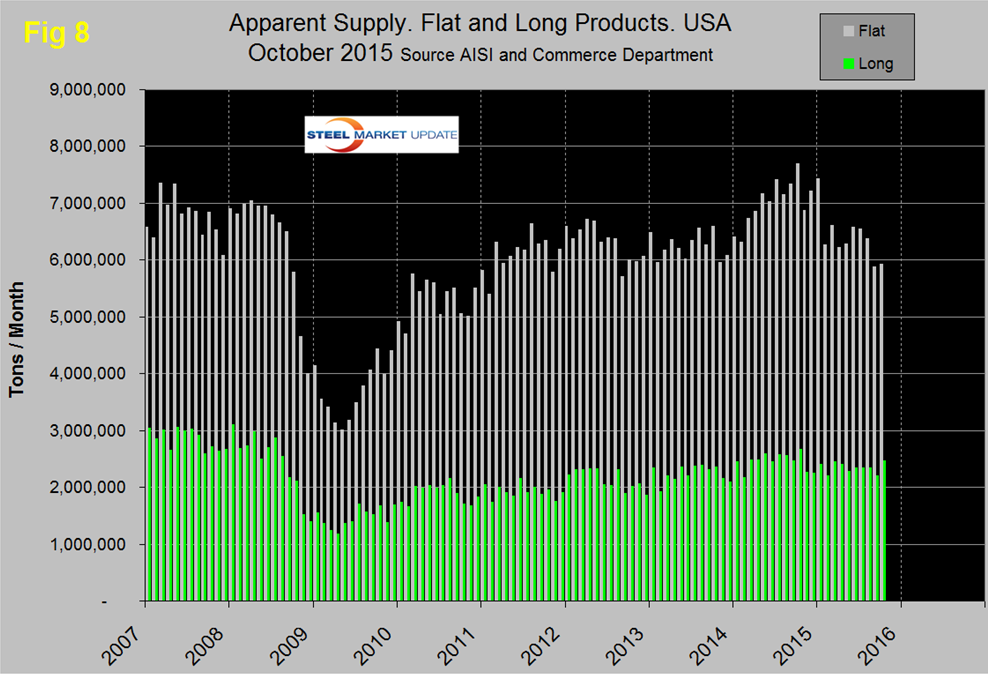

SMU comment; last month we reported that the September and October data was ugly and the November update is no better. On a year over year basis both shipments and intake were down for all products. Inventories in terms of MoH were also down y/y in November for all products except sheet which was up by 0.8 percent. Figures 2, 4, 5 and 7 show that there has been a distinct decline in shipments for all products since the middle of last year. This MSCI data is now looking more like our report of total supply to the market which is based on AISI shipment and import data. Total supply of flat rolled products peaked in November last year, dropped sharply in February then through August didn’t change much. However in September and October supply was the lowest since October 2012 as shown in Figure 8.

Note: this supply data is one month behind the MSCI information.

The SMU data base contains many more product specific charts than can be shown in this brief review. For each product we have ten year charts for shipments, intake, inventory tonnage and months on hand. Some readers have requested these extra charts for a particular product and others are welcome to do so.