Market Segment

March 19, 2015

Service Center Intake, Shipments and Inventory in February

Written by Peter Wright

Total service center carbon steel shipments in February decreased by 182,800 tons to 3.185 million tons. Shipping days at 20 were one less than February. On a tons per day basis (t/d) shipments decreased from 160,400 in January to 159,300 in February.

![]()

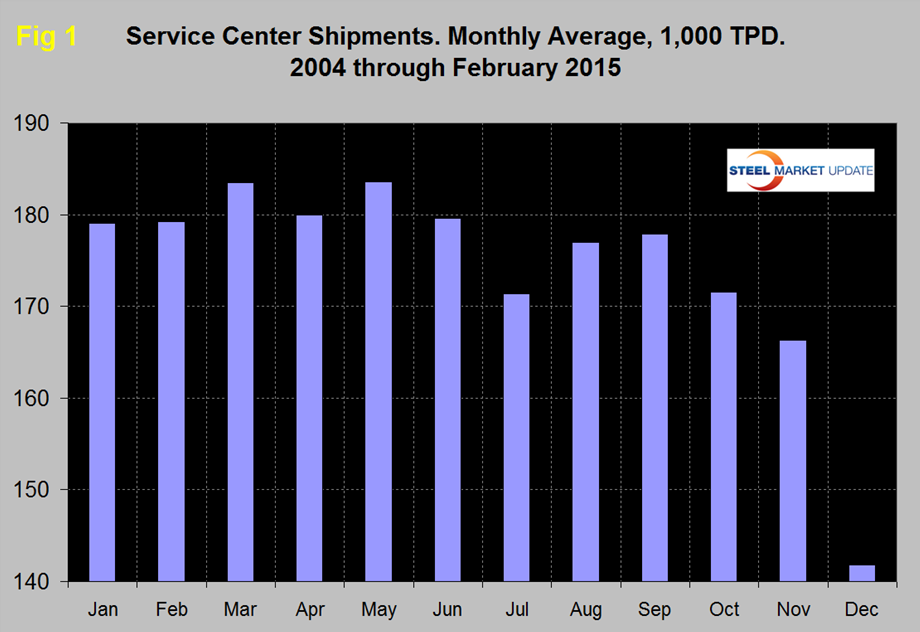

In the eleven years since 2004 February shipments on average have been 0.1 percent higher than January. This year February was down by 0.7 percent from January so this was not a particularly good result. Figure 1 demonstrates the seasonality of service center shipments and why comparing a month’s performance with the previous month is usually misleading. For this reason in the SMU analysis we always consider year over year changes.

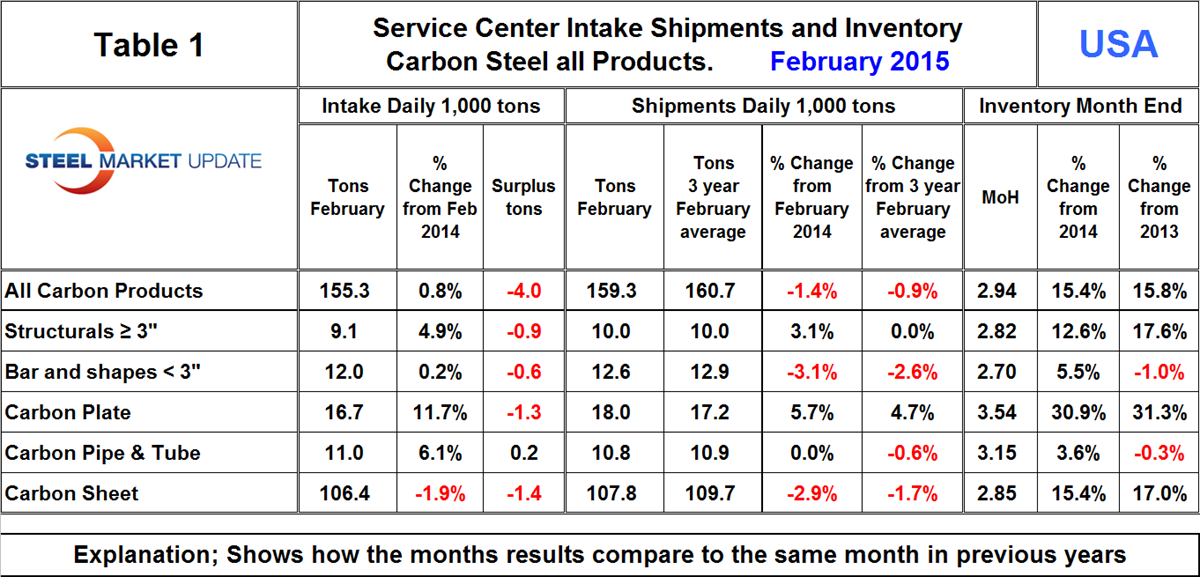

Table 1 shows the performance by product in February compared to the same month last year and also with the average t/d for the last three Februarys. We then calculate the percent change between February 2015 and February 2014 and with the 3 year February average. We hope this give the best view of market direction.

In February intake at 155,300 tons was 4,000 tons less than shipments. For all products except pipe and tube, intake was less than shipments. Shipments of all products on a t/d basis were down by 1.4 percent from February last year and down by 0.9 percent from the average February shipments for 2015, 2014 and 2013. The fact that the single month growth comparison is worse than the three year comparison is an indication that momentum is negative and growth is slowing.

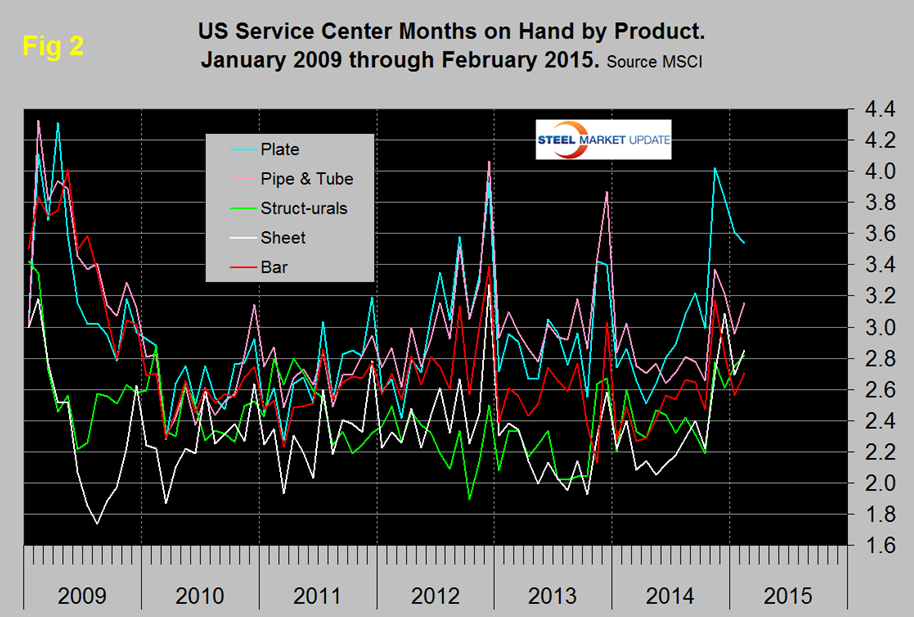

February closed with months on hand (MoH) at 2.94, up from 2.8 at the end of January. Compared to the end of February last year, moth end inventories were up by 15.4 percent in total. All products had a year over year inventory increase led by plate which was up by 30.9 percent. Figure 2 shows the MoH by product monthly since January 2009. Plate products shot up to over 4 MoH at the end of November and were still high at 3.54 at the end of February.

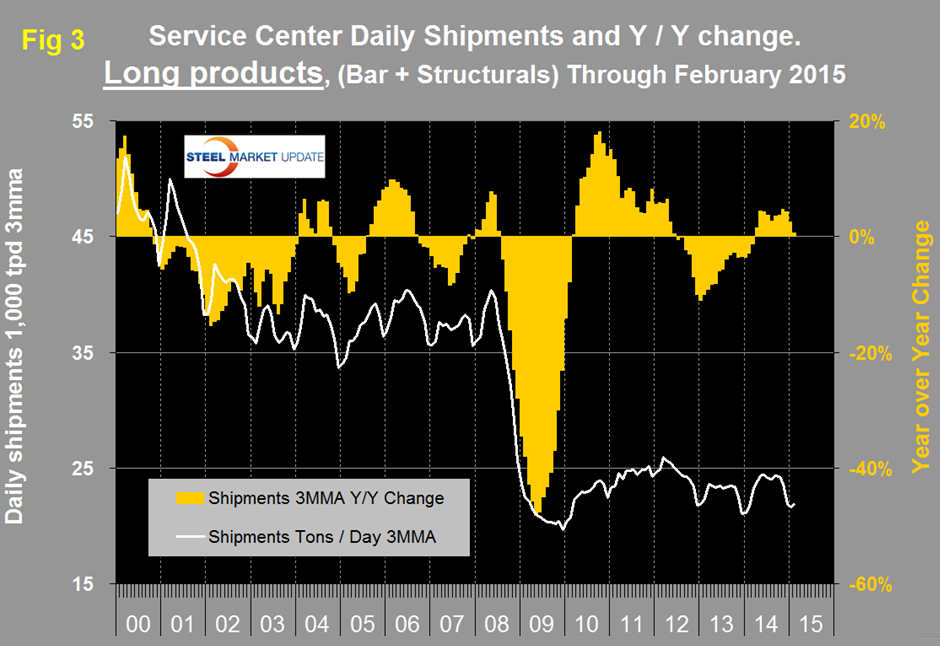

There continues to be a wide difference between the performances of flat rolled (sheet + plate) and long products (structurals + bar) at the service center level. Long products have had a very poor recovery from the recession. On a 3MMA basis y/y, the growth of shipments was negative for 21 straight months until April last year which was the first of eleven straight months of growth. However on a y/y basis growth slowed to 2.5 percent in January and was only 0.6 percent in February (Figure 3).

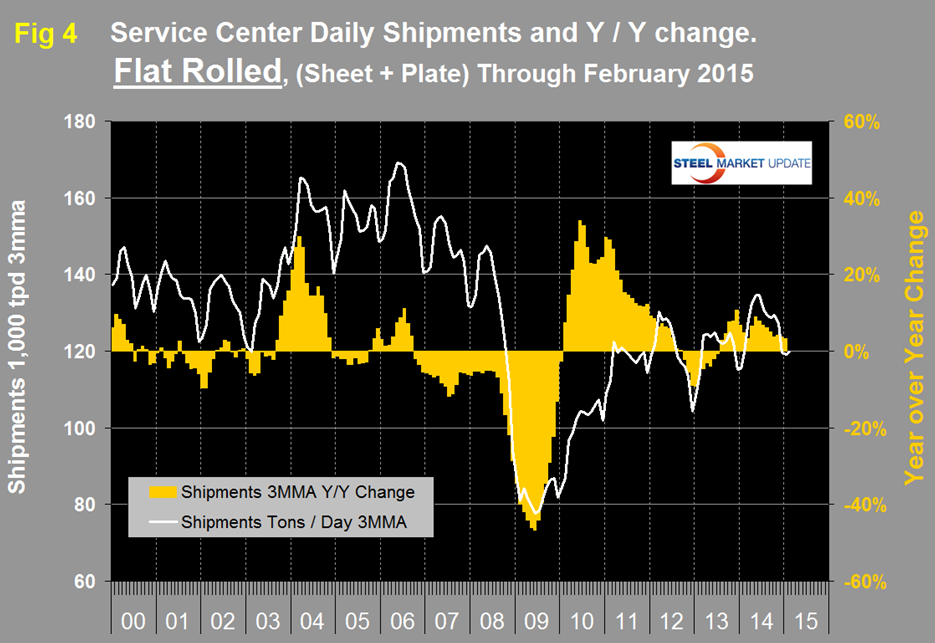

Flat rolled has had a much better recovery since mid-2009 and had positive y/y growth for 18 straight months through January. In February growth slowed to zero (Figure 4).

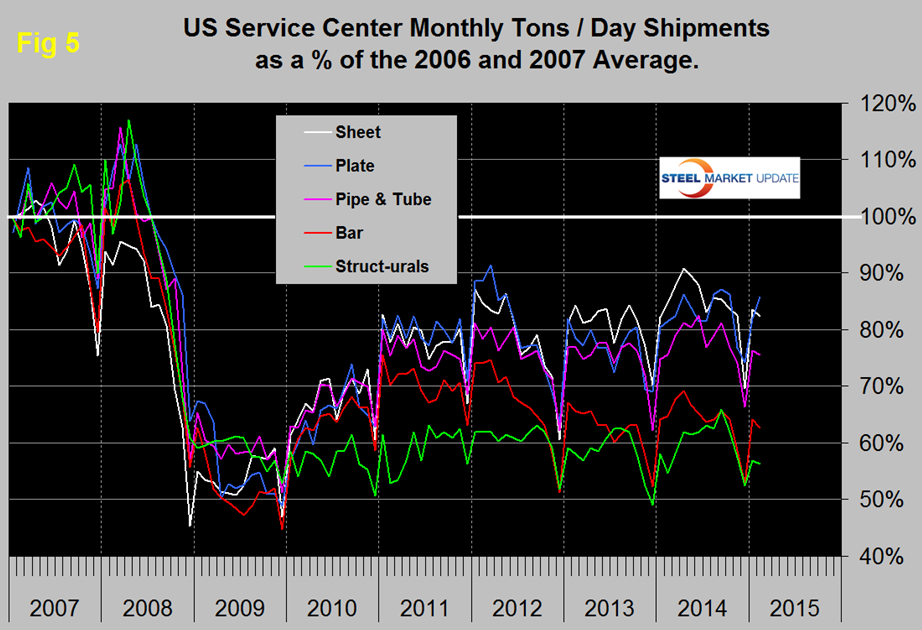

In 2006 and 2007, the mills and service centers were operating at maximum capacity. Figure 5 takes the shipments by product since that time frame and indexes them to the average for 2006 and 2007 in order to measure the extent to which service center shipments of each product have recovered.

Again it can be seen that bar and structurals have the worst record. Sheet and plate have had the best recovery since the recession followed by tubulars. Even so the recovery of sheet is only at 82.4 percent and plate at 85.7 percent. The total of carbon steel products is now at 75.0 percent of the shipping rate that existed in 2006 and 2007, with structurals and bar at 56.3 percent and 62.7 percent respectively. The recovery of the service center sector has been much slower than has been experienced by the mills. Presumably this is because more buyers are purchasing mill direct and this is probably particularly true of long products. In addition long products being more construction oriented are suffering from the slow recovery of that business sector.

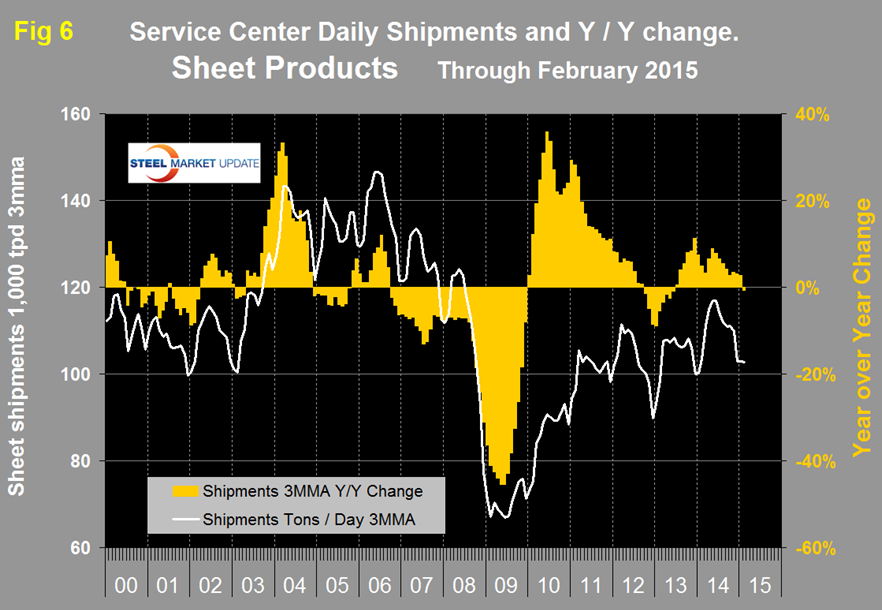

MSCI uses product nomenclature flat and plate. In this analysis at SMU we replace the term flat with sheet. By our interpretation of the MSCI’s data their definition of ‘flat’ is all hot rolled, cold rolled and coated sheet products. Since most of our readers are sheet oriented we have removed plate from Figure 4 to highlight the history of sheet products which are shown in (Figure 6).

Following the strong post-recession recovery, sheet products experienced 9 months of decline from October 2012 through June 2013. This was followed by eighteen months of growth through January this year but February slipped back into negative territory at -0.7 percent year over year.

The SMU data base contains many more product specific charts than can be shown in this brief review. For each product we have ten year charts for shipments, intake, inventory tonnage and months on hand. Readers are welcome to these on request.